Boat engine vibration: understand the causes, diagnose and reduce vibrations

Your boat engine is vibrating more than usual—enough to make cruising uncomfortable, worry the crew, or make you fear a breakdown? Boat engine vibrations can come from something simple (a damaged propeller) or from a more serious issue (alignment, drivetrain, engine mounts). In this guide, we cover the causes, the types of vibration, an easy diagnosis method, and solutions to get back to smooth running—without “guessing”.

Looking for the big picture (diagnosis + budget + decision)? Start with our boat engine repair guide, then come back here for the “vibrations” case.

- Understanding boat engine vibration: what it is (and why it matters)

- What are the types of vibration on a boat?

- Most common causes (propeller, drivetrain, mounts, engine…)

- Step-by-step diagnosis: finding the source of vibration

- What to do at sea if vibration suddenly appears

- Solutions and best practices to reduce vibration

- Preventing vibration from coming back: key maintenance checks

- Summary table: “symptom → likely causes → quick checks”

- Useful links: parts often involved

- Quick FAQ

Understanding boat engine vibration: what it is (and why it matters)

A boat engine vibration is an abnormal oscillation transmitted by a moving component (engine, drivetrain, propeller) to the boat’s structure. You may feel it in the wheel, tiller, floor, transom, or even throughout the boat depending on the frequency.

The key point: vibration is not just “discomfort”. It can indicate a mechanical imbalance (a rotating part is “running off”), abnormal play (worn part), or resonance (the boat amplifies a frequency). Over time, it stresses fasteners, engine mounts (silentblocks), the drivetrain, and sometimes sealing systems depending on the setup—and increases the risk of failure.

What are the types of vibration on a boat?

Vibration can be classified in different ways. For practical troubleshooting, these categories are the most useful:

1) “RPM-related” vibration (frequency increases with engine speed)

Typically linked to a rotating component: propeller, shaft, coupling. The higher the RPM, the faster and stronger the vibration feels.

2) “Load-related” vibration (mostly in gear, under acceleration)

Often linked to propulsion (propeller, shaft line, saildrive) or alignment. It can be mild in neutral and noticeable as soon as the propeller is “pushing” water.

Alignment means the engine axis and drivetrain axis are perfectly in line, without stress.

3) “Irregular” vibration (shaking, misfires, jerks)

This usually points to an uneven engine run (misfires, fuel supply issues, cylinders not balanced) or a mounting issue that lets the engine move excessively.

4) Resonance / structural vibration

Sometimes the root cause is “minor”, but the hull or a component (engine cover, floor, bulkhead) starts vibrating at a specific RPM—like an instrument. This is resonance: the structure amplifies a frequency. In that case, vibration can be very strong at one RPM range and then decrease beyond it.

Most common causes (propeller, drivetrain, mounts, engine…)

To keep it simple, vibration usually comes from three zones: propulsion (what pushes the boat), the drivetrain (what links engine to propulsion), and the engine / mounts. Here are the most common causes, from frequent to more critical.

1) Damaged, bent or unbalanced propeller

A slightly bent blade, a strike on a shallow spot, deformation, or even buildup (barnacles, uneven paint) can create a balance issue. The propeller no longer “runs true” and sends vibration through the whole line. This is a classic cause when vibration appears suddenly.

2) Rope, bag, seaweed: partial obstruction on the propeller

A line (rope) caught in the propeller or wrapped around the shaft is very common. It can cause vibration + loss of speed + sometimes a rubber smell (heat). It’s a priority check because running like this can damage sealing parts (depending on the setup).

3) Play or wear in the drivetrain (inboard / shaft line / saildrive)

Depending on your setup, several components can develop play: guides/bearings, linkages, couplings. When a part no longer guides properly, the shaft can “whip” and vibration increases. In general, the longer you wait, the more other parts can be affected (domino effect).

4) Poor engine/drivetrain alignment

An inboard (shaft line) or drivetrain setup can vibrate if alignment is no longer correct. This can happen after grounding/impact, after work, or simply over time (mounts settling). Result: the drivetrain runs under stress, heats up, wears faster… and vibrates.

5) Worn engine mounts (silentblocks)

Silentblocks (engine mounts) absorb part of the vibration and hold the engine. With age, they compress, crack, or soften. A worn mount can turn a “normal” vibration into noticeable shaking, sometimes with a visibly moving engine.

6) Engine issue: misfires, unbalanced cylinders, fuel, ignition

If the vibration feels like irregular shaking—especially at idle—the source may be the engine: uneven combustion, misfires, fuel supply, or idle adjustment. The sensation is often different from prop imbalance: less “smooth” and more “choppy”. And if you also notice smoke at the exhaust, check our article boat engine smoking.

7) Hull or component resonance (cover, floor, accessories)

A poorly latched engine cover, a loose accessory bracket, a vibrating battery tray, or a floor panel that resonates at a specific RPM can make it feel like “the whole engine is vibrating”, when the cause is actually peripheral. It’s common—and sometimes easy to fix.

Step-by-step diagnosis: finding the source of vibration

The goal is to avoid two classic mistakes: replacing parts at random or continuing to run despite a serious symptom. Here is a simple method that works for most boats.

Step 1 — Describe exactly “when it vibrates”

- At idle?

- Under acceleration?

- At a specific RPM (e.g. between 2500 and 3000 rpm)?

- Only in gear (forward) or also in neutral?

- Sudden onset (after impact, seaweed, rope) or gradual?

- With loss of speed, noise, smell, or alarms?

This “profile” already points you in the right direction: neutral = more likely engine/mounts; in gear = more likely prop/drivetrain.

If vibration comes with a real drop in speed (slower boat, won’t reach normal RPM), also check our boat engine loss of power guide—the two symptoms often go together.

Step 2 — Compare neutral vs in-gear (in harbor, safely)

If vibration is strong in neutral, suspect mounts, loose peripherals, or irregular engine running. If it’s mild in neutral but strong in gear, suspect propeller, shaft, alignment, drivetrain.

Step 3 — Quick visual inspection (often obvious)

- Propeller: blades intact, no visible impact, no deformation.

- Rope/bag/seaweed around the propeller or shaft.

- Engine fasteners: nothing loose, no abnormal rubbing marks.

- Peripherals: cover, exhaust, accessories, battery, tank… anything that can vibrate.

Step 4 — Locate where vibration is transmitted the most

Without putting yourself at risk, try to identify where vibration is strongest: transom, cockpit, helm, engine bay, floor. Strong vibration at the stern often points to propulsion/drivetrain.

Step 5 — Check engine mounts (silentblocks)

A simple check: at idle, observe (or have someone observe) whether the engine “lifts”, rocks, or shakes excessively. Worn mounts may show abnormal movement.

Warning: never put hands near moving parts.

Step 6 — Inboard / shaft line: suspect alignment and guidance

In-gear vibrations that increase with RPM often point to the shaft line. A full check may require a professional, but you can note: onset after impact, gradual worsening, or unusual leakage/overheating near the shaft exit.

Step 7 — If it feels “choppy”: engine misfire path

If the engine runs unevenly, look at fuel supply, ignition (gasoline), filters, or an idle setting that’s too low/unstable. If the engine starts then stalls (or stalls under acceleration / when hot), see our boat engine stalling guide.

When to stop diagnosing and call a professional

- Sudden, very strong vibration + major loss of speed

- Metallic noise, knocking, grinding, or burning smell

- Vibration rapidly getting worse

- After a significant impact/grounding

- Leakage, abnormal overheating, or doubts about sealing (depending on setup)

What to do at sea if vibration suddenly appears

At sea, the goal is not to “push through” at all costs: you must stay safe and avoid making things worse. Here is a simple approach:

- Reduce throttle immediately and return to a low, stable RPM.

- Check alarms (temperature, oil, charging) and warning lights/sounds — if temperature rises, also see our boat engine overheating guide.

- Assess handling: does the boat respond normally?

- If vibration is very strong, shift to neutral and observe: does it persist?

- If you suspect rope (line/net), don’t insist: secure the situation, then check as soon as possible.

- If in serious doubt, return cautiously or request assistance depending on your situation.

Solutions and best practices to reduce vibration

Solution 1 — Propeller: inspection, repair, balancing

A healthy propeller is one of the best levers. If a blade is damaged, imbalance creates constant vibration. Depending on the case, repair or replacement is best. After an impact—even a small one—a check is often worthwhile.

Solution 2 — Replace worn engine mounts

When mounts are compressed or cracked, vibration passes into the hull and drivetrain. Replacing them often brings an immediate comfort and reliability gain. Note: on some setups, replacement requires adjustment to restore proper alignment.

Solution 3 — Check / redo alignment (especially inboard)

Proper alignment prevents stress, premature wear, and vibration. It’s especially important after work, after an impact, or if you notice gradual deterioration. A professional has the right methods and tools for fine alignment checks.

Solution 4 — Fix play and wear in the drivetrain

If a guiding component is worn, vibration won’t “go away” by itself. Once the part is identified (guidance, linkage, coupling…), restoring it is the healthiest route. The longer you wait, the more other parts can suffer.

Solution 5 — If it’s engine-related: stabilize the way it runs

For an engine that shakes at idle or misfires, start with basics: filtration, fuel quality, idle setting, and ignition checks (gasoline). An engine that runs smoothly naturally transmits fewer vibrations.

Preventing vibration from coming back: key maintenance checks

Prevention is not doing everything all the time—it’s doing the right checks at the right moment. A few habits greatly reduce the risk of abnormal vibration:

- Inspect the propeller regularly (impacts, deformation, nicks) and after any “suspicious” outing.

- Avoid ropes nearby during maneuvers and check if in doubt.

- Monitor engine mounts: visual condition, settling, new vibration.

- After grounding: consider a drivetrain/alignment check (even if “it still runs”).

- Maintain fuel filtration to limit uneven running.

Summary table: “symptom → likely causes → quick checks”

This table helps you sort things quickly. It does not replace a professional diagnosis, but it prevents going down the wrong path.

| Symptom | Likely causes | Quick checks |

|---|---|---|

| Vibration mainly in gear, mild in neutral | Damaged/unbalanced propeller, obstruction (rope), drivetrain, alignment | Inspect propeller, look for rope/seaweed, note sudden onset, test at low RPM |

| Vibration at idle (neutral) | Worn mounts, loose peripherals, uneven engine running | Observe engine movement, check covers/fasteners, listen for smooth idle |

| Vibration increases with RPM, “smooth” sensation | Imbalance of a rotating part (prop/shaft/linkage) | Compare neutral vs in gear, visual inspection, note after impact |

| “Choppy” shaking, uneven engine | Misfires, fuel supply, ignition (gasoline), idle adjustment | Listen for misfires, verify basic maintenance, get checked if persistent |

| Strong vibration at a specific RPM, then less beyond | Structural resonance, resonating component | Find vibrating area (cover, floor, bulkhead), check fasteners/isolation |

| Sudden vibration + loss of speed | Rope/bag, damaged propeller, impact | Reduce RPM, return cautiously, check as soon as possible, don’t insist |

Useful links: parts often involved

Depending on the source of vibration, these part families are often involved. The goal is not to replace everything, but to target the right area once the cause is identified.

- Vibration absorption: engine mounts / silentblocks

- Propulsion: propellers · mounting kits & extensions

- Engine ↔ drivetrain connection: couplings · couplings & gearboxes

- Shaft line: propeller shafts · cutless bearings (hydrolube)

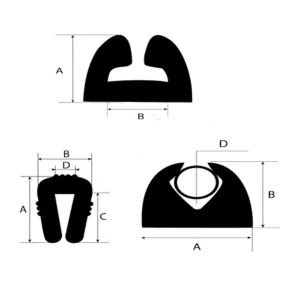

- Sealing (shaft line): stuffing boxes

- Sealing (saildrive): saildrive boots

- Maintenance for a “smooth” engine: fuel filters · oil filters · spark plugs

- Cooling (prevents side issues): water pump impellers

Quick FAQ

What most often causes boat engine vibration?

The most common causes are an unbalanced propeller (impact, deformation), an obstruction (rope, seaweed), worn engine mounts, or a drivetrain/alignment issue depending on the setup.

How can I tell if vibration comes from the propeller or the engine?

If it vibrates mainly in gear (and much less in neutral), focus on propulsion/propeller first. If it vibrates already in neutral, look at mounts, loose peripherals, or uneven engine running.

Is it dangerous to run with boat engine vibration?

It can be. Strong or new vibration may indicate imbalance or play that accelerates wear and can lead to failure. If vibration is significant, reduce RPM, don’t insist, and get it checked.

Why does it vibrate mostly under acceleration?

Acceleration puts the drivetrain under load. An imbalance or imperfect alignment often shows more clearly at that moment. It’s typical of issues related to the propeller, shaft line, or couplings.

Can vibrations be “adjusted” like an engine tune?

Sometimes yes, sometimes no. If vibration is due to unstable idle, adjustable mounts, or alignment to be corrected, adjustment may help. But if a part is bent (prop/shaft) or worn (play), repair/replacement is usually required.

When should I call a professional?

As soon as vibration is sudden and strong, comes with loss of speed, abnormal noise, smell or overheating, or after an impact. A quick check is better than chain damage.