Boat engine repair: diagnosis, costs, and deciding whether to repair or replace

An engine breakdown at sea or in the marina is rarely “just” a breakdown: it’s a ruined outing, stress, and an immediate question: what can I check right now… and when should I hand things over to a boatyard? This guide helps you run a simple diagnosis, understand the most common faults, set expectations on costs, and choose the best option: repair, rebuild, or replace the engine.

- Before repairing: method and limits (onboard vs boatyard)

- Best reflexes during a breakdown (safety + avoid making it worse)

- Quick diagnosis: understanding where the fault comes from

- Common issues: symptoms, likely causes, sensible solutions

- When to go to a boatyard: the signals that matter

- How much does boat engine repair cost? Simple benchmarks

- Repair, rebuild or replace: deciding with confidence

- When to consider a complete engine (engine, block, pack)

- In the South: two boatyards to contact (La Seyne & Marseille)

- Summary table

- FAQ

Before repairing: method and limits (onboard vs boatyard)

The best way to handle an engine issue is to avoid two traps: taking everything apart in a rush… or, on the contrary, pushing on while the engine is clearly warning you. The most effective approach is simple: start with what is visible, logical, and reversible, then delegate as soon as it becomes technical, risky, or uncertain.

This guide distinguishes two levels:

Level 1 (reasonable checks): visual checks, fuel, connections, routine maintenance, and replacing consumables only when they clearly match the symptoms.

Level 2 (workshop intervention): anything involving internal mechanics, complex adjustments, modern injection, compression checks, drivetrain/transmission, or safety.

The goal: give you a clear method to act usefully, without buying parts “at random” and without turning a medium issue into a big bill.

Best reflexes during a breakdown (safety + avoid making it worse)

Before looking for the cause, protect the boat, the crew… and the engine. Some issues can be handled calmly; others must be stopped immediately.

Three reflexes that save time:

- Secure your situation (traffic, anchoring, weather, plan to return).

- Observe: smoke (colour), smells (fuel, burnt), noises (metallic, knocking), vibrations, warning lights/alarms.

- Note the context: prop strike, recent refuel, dirty water, rough sea, recent maintenance, long storage, etc.

When you should shut down immediately: suspected overheating, uncertain cooling (especially outboards), a new metallic noise, burnt smell, persistent thick smoke, or a sudden major performance drop.

Quick diagnosis: understanding where the fault comes from

An engine (outboard or inboard) needs a simple chain: air + fuel + ignition (gasoline), compression, and cooling. The issue usually sits in one of these blocks. Here is a fast way to “classify” the problem before hunting for a part.

- The engine won’t start at all: starter silent/slow (electrical), or starter OK but the engine won’t “catch” (fuel/ignition/controls/safety).

- The engine starts then stalls: often fuel supply, air leak, clogging, unstable idle, or a fault that triggers when hot.

- The engine overheats / cooling is weak: prioritise the water circuit (overheating can be very expensive).

- Power loss, vibrations, noises: prop/gearcase/shaft line, mounts, fuel, or a protection/derate linked to an alarm (depending on engines).

From there, you can tackle the symptom in a structured way.

Common issues: symptoms, likely causes, sensible solutions

1) Boat engine won’t start

This is the classic case where you can lose a lot of time… even though the cause is sometimes simple. Start with what requires no special tools and no heavy dismantling.

Priority checks: kill switch in place, control in neutral, battery charged, terminals clean and tight, and connectors with no visible corrosion.

Then, depending on the engine type: on gasoline, ignition and fuel supply are frequent suspects (spark plugs, filter, fuel). On diesel, think fuel supply (air in the line, diesel filter, water in fuel) and preheating (depending on setup).

If your diagnosis clearly points to a consumable, you can check: spark plugs and fuel filters. Otherwise, avoid buying “at random” and move to a more supervised diagnosis.

Go further: see the full guide boat engine won’t start (causes & solutions).

2) The engine starts then stops / stalls at idle

An engine that starts and then stalls often indicates a fuel-supply problem: contaminated fuel, a clogged filter, an air leak, a blocked tank vent, or idle control/management. It’s frustrating, but often solved by going back to basics.

Start by checking consistency: fresh fuel, ventilated tank, hoses in good condition, primer bulb (outboards) properly firm, and no unusual leak or smell.

If “clogged fuel supply” is a credible scenario, then gasoline filters and more broadly fuel filters are natural checkpoints.

Go further: engine stalls (diagnosis & solutions).

3) Overheating / cooling issue (e.g., outboard not peeing water)

Here, the priority is simple: protect the engine. If the engine overheats, an alarm triggers, or cooling seems absent, don’t push on.

On outboards, the lack of a tell-tale stream is a useful signal (even if it isn’t an absolute proof of internal circulation). Common causes: clogged intake, debris, worn impeller. The impeller is a rubber piece inside the water pump: it pushes water through the circuit and wears over time, especially if the engine has run without water.

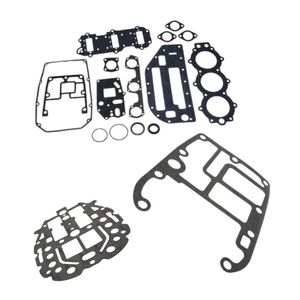

If this diagnosis is consistent, see the category impellers. For overall maintenance (lubrication, prevention), the oils category can also be useful.

Go further: boat engine overheating (full guide).

4) Power loss

Power loss can be gradual (clogging, fuel) or sudden (prop strike, overheating, a fault that triggers). To move efficiently, first look for an “event”: a strike, refuel, dirty water, long storage.

Check the prop (nicks, deformation), algae/lines, and whether an alarm appeared. If the fuel path is plausible, the filter is a frequent cause (not systematic).

Go further: power loss (causes & solutions).

5) Unusual vibrations / unusual noises

Vibrations and noises should be taken seriously, especially if they appear suddenly. A metallic noise, a new knock, or strong vibrations can indicate a mechanical issue (prop, drivetrain, mounts, alignment).

A useful first action is to check what’s accessible: prop, foreign object, visible play, unusual leak. If symptoms persist or worsen, a boatyard is usually the safest option.

Go further: engine vibration (full guide).

6) Smoke (white/black/blue) and misfires

Smoke and misfires don’t all mean the same thing, but they indicate the combustion is not “normal”. The key is to correlate the symptom with the context: cold/hot, idle/load, after refuelling, after long storage.

On gasoline engines, misfires can be linked to ignition (spark plugs, related parts) or fuel supply. On diesel, focus often goes to fuel quality and the supply circuit. With persistent smoke, marked power loss, or abnormal noise, workshop diagnosis is preferable.

Go further: boat engine smoke (white/black/blue).

When to go to a boatyard: the signals that matter

There’s no single universal answer: it depends on the engine, access, your skill level, and how much reliability you need. However, some signals make the decision much easier.

Boatyard recommended when:

- overheating repeats, or cooling is uncertain;

- a metallic noise appears, especially if it follows RPM;

- vibrations increase or appear after a serious strike;

- the fault is intermittent and returns despite sensible checks;

- you suspect an “internal engine” issue (compression, rings, valves, etc.);

- drivetrain/gearcase/shaft line may be involved.

A good compromise, when possible, is to prepare the visit: clear symptoms, context, maintenance history, and what you have already checked. This often speeds up diagnosis and avoids wasted hours.

How much does boat engine repair cost? Simple benchmarks

Costs vary greatly by region, engine type, accessibility, and the time needed to confirm the cause. To set a budget, it helps to separate two items: parts and labour. Labour is what rises fastest when the fault is unclear or intermittent.

Labour: in many workshops, rates frequently sit around €60 to €100 incl. VAT per hour, depending on complexity and urgency. (Each yard has its own pricing and packages.)

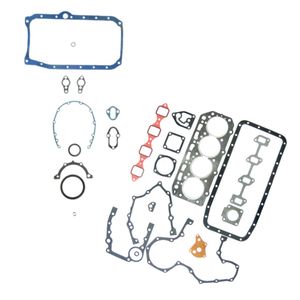

Common jobs: when the cause is well identified (targeted maintenance, filter, impeller, oil change, etc.), the bill is often more manageable. Conversely, lengthy fault-finding, advanced corrosion, or internal engine work quickly pushes the budget into amounts where comparing with replacement makes sense.

For maintenance (engine oil, gear oil, consumables), you can check: oils, and, for practical tools, gearcase tools.

Repair, rebuild or replace: deciding with confidence

The decision is rarely “technical” only: it also depends on your use, your schedule (season), and the reliability you expect. To decide, ask yourself these questions, in this order.

- Is the fault clearly localised (cooling, fuel, maintenance) or diffuse (general wear)?

- Does the engine have a reliable history (regular maintenance, limited corrosion, stable operation before the fault)?

- Are parts and labour still proportional to the boat’s value and your use?

- Is the recurrence risk low (cause identified) or high (uncertain fault, corrosion, repeated overheating)?

- Do you need availability immediately (quickly back on the water) or can you wait?

In practice, the more targeted the issue, the more attractive repair is. The more uncertain and labour-heavy it becomes, the more logical it is to evaluate replacement.

When to consider a complete engine (engine, block, pack)

Replacing the engine isn’t only for “extreme failures”. It can be rational when workshop costs become hard to control, or when you need reliability and availability quickly. Depending on your configuration, you can compare:

- Outboard engine: full replacement often suits small and mid-size boats → see outboard engines.

- Engine block: interesting for certain inboard setups → see engine blocks.

- Engine pack: a more complete solution (marinised engine + accessories depending on pack) → see engine packs.

And if your first need is to find the right reference (part or compatibility), start here: find your parts via exploded views.

In the South: two boatyards to contact (La Seyne & Marseille)

If you want to entrust mechanical work to a boatyard in the South, you can consult these two organisations:

- Plaisance Yachting Services (PYS) – La Seyne-sur-Mer: official website

- CS Refit – Marseille: official website

For help identifying parts and consumables, you can also contact Dam Marine: +33 4 94 27 36 62 · contact@dam-marine.com.

Summary table

A quick guide to summarise the essentials: symptom, first useful action, possible parts if relevant, and signals that justify a boatyard. The “detailed article” links are planned to build your future content cluster.

| Symptom | First useful action | Possible parts (if relevant) | Boatyard recommended if… | Detailed article (to link) |

|---|---|---|---|---|

| Won’t start | Kill switch, neutral, battery/terminals, fuel | Spark plugs, fuel filter | Abnormal noise, burnt smell, persistent fault, uncertain diagnosis | To complete |

| Starts then stalls / stalls at idle | Fuel, tank vent, hoses, priming (outboards) | Gasoline filter | Intermittent fault, hot fault, injection/electronics suspected | To complete |

| Overheating / uncertain cooling | Reduce/shut down, check intake and circulation | Impeller, oils (maintenance) | Repeated overheating, alarm, uncertain internal circulation | To complete |

| Power loss | Check prop, algae/lines, fuel, filter | Fuel filter (if fuel-related) | After a serious strike, vibrations, recurring fault despite checks | To complete |

| New vibrations / noises | Check prop and accessible items, stop if metallic noise | — | Strong vibrations, metallic noise, drivetrain/alignment suspected | To complete |

| Smoke / misfires | Note context (cold/hot/load), avoid pushing on | Spark plugs (gasoline, if misfiring) | Persistent smoke, marked power loss, abnormal noise, internal doubt | To complete |

FAQ

What can you realistically do yourself for boat engine repair?

Most boaters can handle basic diagnosis, visual checks, and some routine maintenance (done properly and according to the engine manual). However, as soon as you get into internal mechanics, modern injection, compression issues, or drivetrain/transmission, a boatyard is usually more appropriate.

Why is my outboard not “peeing” water?

Common causes are within the cooling circuit: a blocked intake, debris, or a worn impeller. Because overheating can damage the engine quickly, treat this symptom as a priority.

How much does it cost to repair a boat engine?

It mainly depends on diagnostic time and the scope of the work. When the cause is clear (targeted maintenance, filter, impeller, etc.), the budget is often manageable. When the fault is intermittent or linked to corrosion and major dismantling, labour dominates. The best way to control it is to arrive with precise symptoms and a maintenance history.

Is a full rebuild worth it?

Yes in some cases: well-maintained engine, sound base, limited corrosion, available parts, and appropriate use. If the rebuild looks long, uncertain, and labour-heavy, it becomes relevant to compare with a replacement solution.

Repair or replace the engine: what’s the most important criterion?

The most useful criterion is often the combination of: identified fault + recurrence risk + total budget (parts, labour, downtime). A clear fault repairs well. An uncertain fault that eats workshop hours often justifies comparing with a complete engine, block or pack.

Does Dam Marine perform repairs?

Dam Marine specialises in selling parts and providing advice. For workshop work, it’s recommended to go through a boatyard. Links to PYS (La Seyne-sur-Mer) and CS Refit (Marseille) are provided above for readers in the South.

Conclusion: a successful repair starts with a calm, structured diagnosis. Address what is logical and verifiable first, then hand over to a boatyard as soon as safety, complexity, or uncertainty takes over.