Boat engine power loss: causes, diagnosis and solutions (outboard & inboard)

Underway, boat engine power loss doesn’t always look like a clear-cut breakdown: the engine runs, but the boat accelerates less, speed drops, or the engine won’t rev up. Sometimes it stalls when you accelerate or shows misfires. In every case, the right reflex is the same: identify whether the loss comes from the engine itself, the fuel supply, the cooling system, or the transmission/propeller. This guide gives you a clear method, simple checks, and practical solutions for the most common situations, with a focus on outboards and inboards.

Looking for the big picture (diagnosis + budget + decision)? Start with our boat engine repair guide, then come back here for the “power loss” case.

04 94 27 36 62 · contact@dam-marine.com

- Spot the symptoms: rpm drop, speed loss, stalling

- Safety: what to do immediately at sea

- 10-minute quick diagnosis (the checks that pay off)

- Cause #1: fuel & supply (gasoline / diesel feed)

- Ignition & combustion (gasoline) / injection (diesel)

- Cooling, overheating and protective mode

- Propeller, hull, settings: when the engine is fine but the boat won’t go

- Outboard focus: lower unit, hub, ventilation/cavitation

- Inboard focus: shaft line, gearbox, V-drive/Z-drive

- Solutions: what to replace, what to clean, what to adjust

- Prevent power loss: simple, effective routines

- Summary (table): symptom → likely causes → checks → parts

- FAQ

1) Spot the symptoms: rpm drop, speed loss, stalling

Before opening a hatch or ordering a part, clarify one thing: “power loss” can mean several different things on a boat. And the diagnosis is not the same depending on the symptom.

The 4 most common situations

A) The engine won’t rev up

You push the throttle, but rpm plateaus. This typically points to a fuel supply issue, a protective mode (overheating, sensor), an ignition problem (gasoline), or something that “drags” the propulsion (propeller, hull, transmission).

B) The engine revs up but speed drops

Here, the engine produces energy, but it doesn’t turn into thrust efficiently: damaged propeller, spinning hub, ventilation/cavitation, fouled hull, or slip somewhere in the driveline depending on the setup. This is a classic case of boat speed loss even though the engine “seems” to run normally.

C) The engine stalls when accelerating

An outboard that stalls on acceleration or an inboard that bogs down when you reapply throttle often points to a fuel feed issue (air leak, clogged filter, water in fuel, weak pump) or an ignition/engine management issue on newer systems.

D) “My boat won’t move” (not enough thrust)

Here, you need to separate: is the boat struggling to get on plane (planing mode)? Is thrust irregular? Does it happen only when loaded, in rougher seas, or after long storage? Reading the context helps you go fast.

2) Safety: what to do immediately at sea

A power loss can be minor (dirty hull, clogged filter), but underway it quickly becomes a safety issue. Good reflexes:

- Reduce throttle and stabilize rpm (limits worsening and helps you listen for abnormal noises).

- Check your surroundings: drift, traffic, proximity of hazards, ability to return at the current rpm.

- Watch temperature and alarms. If overheating is indicated, shut down if necessary.

- Avoid long full-throttle tests until the cause is identified.

- If in doubt: call for assistance rather than forcing a fragile system.

3) 10-minute quick diagnosis (the checks that pay off)

The goal is to spot the most common causes without complex tools. This checklist works for small sailboat auxiliaries as well as higher-power setups.

Step 1 — Simple clues (sound, smoke, cooling water)

- Telltale water stream (outboard): weak or irregular flow = cooling suspect.

- Unusual smell (fuel, rubber, hot) = fuel or overheating suspect.

- Smoke: black (rich combustion / lack of air / injection issue), persistent white (needs investigating), blue (oil), depending on the engine. To go further, check our guide on smoke colours and how to interpret them correctly.

- Noises: knocking, whistling, new vibrations = drivetrain/propeller to check. If the vibrations are abnormal or settle in, it’s better to diagnose before pushing on. For that, check our guide on diagnosing a boat engine vibration.

Step 2 — Fuel: “1-minute” checks

- Tank vent: if blocked, the tank pulls vacuum and the engine bogs when accelerating.

- Primer bulb (outboard): if it stays soft or empties, suspect an air leak, fitting, or pump.

- Fuel/water separator: water/debris in the bowl = very likely cause of rough running and power loss.

- Fresh fuel? After storage, degraded/contaminated fuel often makes rpm “plateau”.

Step 3 — Propulsion: propeller and drag

- Propeller: bent blade, impact, fishing line, weeds, rope around shaft/axle = immediate performance loss.

- Hull: a fouled bottom can reduce speed dramatically and mimic an engine problem.

- Trim / attitude: wrong trim can prevent planing and feel like power loss.

Step 4 — Alarms / protective mode

On modern engines, an anomaly (temperature, oil pressure, sensor, injection fault) can trigger a protective mode: the engine runs but power is limited. If you suspect this, note the signals (beeps, warning lights, dashboard message): they are key for reliable diagnosis.

And if, after a shutdown or safety mode, the engine refuses to restart, follow this guide: boat engine won’t start: complete diagnosis

4) Cause #1: fuel & supply (gasoline / diesel feed)

On a boat, fuel supply is often the first suspect because it’s exposed to storage, humidity, condensation in tanks, quick-connect fittings, vibration, and sometimes long fuel lines. It also matches these symptoms well: power loss as soon as you accelerate, stalling on acceleration, outboard misfires, or rpm that plateaus.

4.1 Water in fuel: a very common issue

Water can enter through contamination (refueling), or form by condensation when the tank is left partly empty. Result: unstable combustion, misfires, and power loss. A fuel/water separator is designed to trap water and protect the engine.

To do: inspect the separator bowl. If water/debris is present, drain the bowl and replace the filter element.

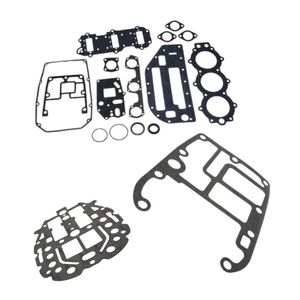

See fuel/water separators

4.2 Clogged filter: the engine “can’t get enough”

Even without water, a dirty filter restricts flow. At low rpm it may cope, but as soon as you demand power, the engine runs lean and bogs down. This strongly matches a gradual loss of power.

4.3 Air leak in the fuel system

A tiny air leak (clamp, quick-connect, aging hose) can disrupt supply. On outboards, the primer bulb and quick-connects are frequent culprits. On diesel, air leaks can cause power loss and difficulty holding rpm under load.

4.4 Blocked tank vent

If the vent is obstructed, the tank creates vacuum and fuel flow drops when accelerating. Sometimes the problem “disappears” when you open the filler cap. That’s a useful clue to test at anchor (carefully).

4.5 Weak fuel pump / worn diaphragm

A pump that’s starting to fail may feed fine at idle but not during planing acceleration. Typical symptom: the boat struggles to get on plane, then power sometimes returns if you back off the throttle.

4.6 Diesel-specific: deposits and primary/secondary filtration

Diesel power loss is very often linked to filtration: tank deposits, microorganisms, a clogged primary filter, then a clogged secondary filter. Since diesel is often stored longer, maintaining the system is essential.

5) Ignition & combustion (gasoline) / injection (diesel)

If fuel supply looks good, move to combustion quality. On gasoline, ignition (spark plugs, coils, connections) is key. On diesel, focus more on injection quality and air intake.

5.1 Gasoline: spark plugs and misfires

Fouled or improperly tightened spark plugs, a weak coil, or an oxidized connection can cause misfires. At sea, humidity and spray encourage corrosion, so this deserves attention.

5.2 Air intake (especially on gasoline inboards)

On some setups, the intake may have a protective device (screen/flame arrestor). If it’s saturated (oil, dust, residue), airflow drops, combustion degrades, and the engine loses power under load.

5.3 Diesel: air, turbo and fouling

On diesels (especially turbocharged), restricted air (hose, filter, fouling) reduces power. Diagnosis often starts from symptoms (smoke, behavior hot, loss under load) and then workshop checks.

5.4 Compression: when to suspect an internal issue

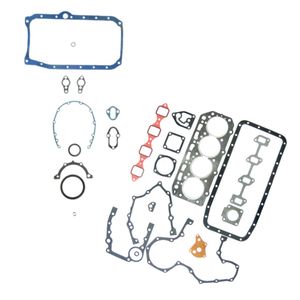

If the power loss is strong and persistent, and no “peripheral” cause is found (fuel, cooling, propeller), a compression test may be relevant. Compression reflects a cylinder’s ability to compress the mixture; if it’s too low, the engine lacks mechanical “strength”. This test requires basic equipment and a proper method.

6) Cooling, overheating and protective mode

Marine engines depend heavily on their environment for cooling: silty water (sand, algae), salt, shells, strainers, and rubber parts that wear out. Overheating can trigger protection: the engine runs but power is limited.

6.1 Impeller: the part to watch

On many engines, the water pump impeller is a small rubber wheel. Over time, the vanes deform, crack or break, reducing cooling flow. This strongly matches power loss that appears “after a few minutes”, especially when hot.

See impellers · See water pumps

6.2 Thermostat: poorly regulated temperature

The thermostat regulates engine temperature. If it stays closed (or opens poorly), temperature rises too much. If it stays open, the engine may run too “cold”, reducing efficiency and potentially increasing fouling in some cases.

6.3 Strainer / seawater filter / water intakes

On inboards, you often have a seawater strainer or filter. If it clogs, flow drops. On outboards, the intake can clog too. After operating in algae/mud-heavy areas, this is a top suspect.

If you suspect a temperature rise (alarm, weakening discharge stream, hot smell), treat it as a priority: diagnosing a boat engine overheating, the guide.

7) Propeller, hull, settings: when the engine is fine but the boat won’t go

An engine can be perfectly healthy and still feel underpowered if thrust is reduced. This is typical when you notice boat speed loss, difficulty getting on plane, or the feeling the boat won’t move despite correct rpm.

7.1 Fouled hull

A fouled bottom greatly increases drag. The boat “sticks” to the water, needs more power for less result, and it’s easy to blame the engine. If the decrease is gradual over weeks/months, the hull is a serious suspect.

7.2 Damaged or mismatched propeller

A bent or chipped blade is enough to reduce efficiency. Another common case: a propeller with the wrong pitch. Pitch is the theoretical distance traveled per propeller revolution: too much pitch = the engine struggles to reach rpm; too little = the engine revs quickly but tops out in speed.

7.3 Trim, load, weight distribution

A stern-heavy load, incorrect trim, or short chop can prevent planing. The engine labors, rpm struggles, and the “power loss” is really a trim/efficiency issue.

8) Outboard focus: lower unit, hub, ventilation/cavitation

The general causes are similar, but outboards have a few specifics that explain why you often see engines that won’t rev up, fuel feed issues, or reduced performance when getting on plane.

8.1 Primer bulb and quick-connect fittings

If the engine improves after you pump the bulb, it’s a strong clue of a supply issue: air leak, check valve, quick-connect, hose or filter. This is easy to confirm by inspecting tightness and hose condition.

8.2 Spinning propeller hub

A propeller may include a hub designed to absorb impacts. If that hub slips, the engine can rev but thrust doesn’t follow. Typical symptom: revs “in the air” or irregular speed.

8.3 Ventilation / cavitation

Ventilation is when the prop draws air (or exhaust gas) and loses bite. Cavitation is different: vapor bubbles form on the prop due to local low pressure and can damage metal. In both cases, thrust drops. Possible causes: damaged prop, mounting height, trim, load, turbulence, anti-ventilation plate, or sea conditions.

8.4 Cooling via the lower-unit impeller

On outboards, the impeller is often in the lower unit. If it weakens, the engine may heat up and then protect itself by limiting power. Preventive replacement is often cheaper than dealing with overheating damage.

9) Inboard focus: shaft line, gearbox, V-drive/Z-drive

On inboards, the driveline may include a shaft line (shaft + bearing + cutless) or a Z-drive/V-drive type transmission. The “felt” power loss can come from abnormal friction, misalignment, or a component that degrades and “absorbs” energy.

9.1 Shaft line: vibrations and friction

If you feel more vibration, or speed drops with a new noise, inspect what you can access: overall condition, play, heat marks, and any foreign object (rope). The cutless bearing guides the shaft; if worn, it can create play, vibrations and loss of efficiency.

9.2 Gearbox: slip, oil and adjustment

The gearbox transmits power to the shaft. If slipping occurs (or oil is degraded), you may see reduced thrust even though the engine doesn’t seem to “strain”. An oil check and professional diagnosis are recommended if you suspect this.

9.3 Z-drive / V-drive: efficiency and maintenance

On these transmissions, mechanical condition and adjustments strongly affect efficiency. Wear, poor maintenance, or a seawater cooling issue can also limit available power.

10) Solutions: what to replace, what to clean, what to adjust

Once you’ve identified the likely family of causes, the goal is to restore stable operation. Here are practical solutions, from most common to more specialized.

10.1 If it looks like a fuel supply issue

- Replace / clean filtration (pre-filter + engine filter depending on setup).

- Check and secure fittings (clamps, quick-connects, hose condition).

- Check tank vent and tank cleanliness.

- Address water contamination: drain separator, use clean fuel, clean tank if contamination is significant.

10.2 If the engine won’t rev up (gasoline)

- Check spark plugs: condition, torque, appearance (fouling, moisture).

- Inspect connections: oxidation, poor contact, tired harnesses.

- Have ignition checked if misfires persist (coils, sensors).

10.3 If power drops when hot

- Cooling first: impeller, water intakes, strainer/seawater filter, thermostat.

- Watch alarms and behavior: protective mode often limits power.

10.4 If speed drops but rpm is correct

- Inspect the propeller (impact, blade damage, deformation) and check efficiency (hub, ventilation/cavitation).

- Look at the hull: fouling = progressive speed loss.

- Adjust trim and weight distribution.

10.5 If you suspect an inboard driveline issue

- Check for foreign objects and overall visible condition.

- Don’t force it if vibrations/noises are abnormal: get it diagnosed (alignment, bearings, gearbox).

11) Prevent power loss: simple, effective routines

A large share of power-loss issues can be prevented with a few habits, especially on boats used seasonally.

Fuel: reduce water and deposits

- Check the fuel/water separator regularly and drain the bowl if needed.

- Avoid long periods with a half-empty tank (reduces condensation).

- Replace filters based on usage and fuel quality.

Cooling: prevent rather than repair

- Replace the impeller following recommendations (often periodic, even if it “still works”).

- Rinse and inspect water intakes, especially after operating in dirty water.

- Watch for hot-running signs (smell, alarms, weaker telltale stream).

Propulsion: propeller and bottom

- Inspect the propeller after an impact or operating in debris areas.

- Keep the hull clean: it’s an often underestimated “performance gain”.

- Match prop pitch and settings to your program (load, sea state, usage).

A word on boat engine lifespan

Boat engine lifespan depends heavily on maintenance, cooling quality, fuel filtration, and respecting operating rpm. A well-cooled, well-fed, properly winterized engine can stay efficient for a long time; overheating and contaminated fuel accelerate wear.

12) Summary (table): symptom → likely causes → checks → parts

| Symptom | Likely causes (boat) | Quick checks | Common parts involved |

|---|---|---|---|

| Engine won’t rev up | Restricted fuel supply, protective mode, too much prop pitch, fouled hull | Tank vent, fuel/water separator, cooling stream, prop/hull condition | Fuel/water separator, Impeller, Propeller |

| Engine revs up but boat speed drops | Spinning hub, ventilation/cavitation, damaged prop, dirty hull | Prop inspection, thrust check, bottom check, trim adjustment | Propeller |

| Engine stalls when accelerating | Air leak, clogged filter, water in fuel, weak pump | Primer bulb (if present), fittings/hoses, separator bowl, tank vent | Fuel/water separator |

| Power drops when hot | Insufficient cooling, thermostat, clogged intakes/filter | Cooling stream, temperature, alarms, inspect intakes | Impeller, Thermostat |

| Vibrations + reduced thrust (inboard) | Foreign object, bearing/cutless, misalignment, driveline issue | Accessible inspection, don’t force if noise is abnormal | Propeller shaft |

FAQ

Can power loss come only from a dirty hull?

Yes. A fouled bottom increases drag and can significantly reduce speed. It’s especially noticeable on planing boats: they struggle to get on plane, consume more, and it feels like an “engine” issue.

Why does power loss show up mostly when accelerating?

On acceleration, the engine needs higher fuel flow and effective cooling. If a filter is close to clogging, if there’s water in the fuel, or if an air leak appears, the engine bogs down right when you ask for power.

How often should you replace an impeller?

There’s no single rule for every engine, but the idea is simple: the impeller is a wear part and can degrade even if the engine still “runs fine”. If you run often, in dirty water, or the boat sat unused for a long time, preventive replacement is often a smart move.

How can you reduce water in gasoline or diesel?

The best reflex is to use a fuel/water separator, check it regularly, and avoid leaving the tank partly empty for long periods (condensation increases). On low-use boats, monitoring fuel quality is essential.

The engine revs, but it feels like it’s slipping—does that mean the propeller for sure?

The propeller is a major suspect (impact, deformation, hub), but other efficiency-related causes exist: ventilation/cavitation, trim settings, fouled hull, and depending on the setup, a driveline component. Context (sea state, load, sudden vs gradual onset) helps a lot.

When should you stop testing and go to a workshop?

If alarms persist, overheating occurs, vibrations are abnormal, you notice an unusual smell, or power loss can’t be explained by the basic checks (fuel, cooling, prop/hull), a professional diagnosis is recommended to avoid making things worse.