Faq Sections

To find all the technical documents, click here. Otherwise you have the option to search through the search bar above your screen.

| BF60A • BFP60A - Maintenance kit 400 h | ||||

|---|---|---|---|---|

| Category | NO | Reference | Designation | Qty |

| 1 | 06161-ZZ3-000 | KIT MAINTENANCE (400 h) | 1 | |

| FILTER CARBURANT (BP) | 2 | 16901-ZZ5-003 | FILTER | 1 |

| 3 | 16919-ZZ5-003 | JOINT TORIQUE | 1 | |

| 4 | 16918-ZZ5-003 | JOINT TORIQUE | 1 | |

| FILTER (HP) | 5 | 16911-ZZ5-003 | HIGH PRESSURE | 1 |

| 6 | 16073-ZZ5-003 | JOINT TORIQUE | 1 | |

| 7 | 16074-ZZ5-003 | JOINT TORIQUE | 1 | |

| ANODE (INTERNAL) | 8 | 12155-ZV4-A00 | ANODE | 3 |

| 9 | 12155-ZV5-000 | ANODE | 1 | |

| 10 | 19371-ZZ3-010 | FRESH JOIN | 1 | |

| 11 | 31754-ZZ3-000 | REGULATOR'S JOIN | 1 | |

| BF80A • BF100A - Maintenance kit 200 h | ||||

|---|---|---|---|---|

| Category | NO | Reference | Designation | Qty |

| 1 | 06510-ZY9-000 | KIT MAINTENANCE (200 h) | 1 | |

| VIDANGE MOTOR | 2 | 15400-RTA-003 | FILTER CARTOUCHE OIL (MAHLE TENNEX) | 1 |

| 3 | 90601-ZE2-000 | VIDANGE ROUND, 12MM | 1 | |

| REFRIDING CIRCUIT | 4 | 19300-ZW9-003 | THERMOSTAT (60°C - BLOC) | 1 |

| 5 | 19300-ZY6-003 | THERMOSTAT (50°C - CULASSE) | 1 | |

| 6 | 19317-ZW9-000 | JOINT TORIQUE, COVER COVER OF THERMOSTAT | 1 | |

| 7 | 1921-ZY9-H01 | TURBINE | 2 | |

| 8 | 1931-ZY9-H01 | POMP PLACTURE | 1 | |

| 9 | 1934-ZW1-B00 | PLAQUE B JOIN | 1 | |

| NODE (EXTERNAL) | 15 | 06411-ZW1-0020 | ANODE | 1 |

| 16 | 41109-ZW1-B00 | ANODE | 2 | |

| 17 | 90205-ZY1-000 | ECRO-FREIN, 6MM | 1 | |

| 18 | 90225-HW1-670 | EPULEY VIS, 6X35 | 1 | |

| VIDANGE EMBASE | 19 | 90101-ZW9-003 | CONTROL VISIT | 1 |

| 20 | 90120-ZY3-000 | VIDANGING VISIT | 1 | |

| 21 | 91301-ZW4-003 | JOINT TORIC, 6.9X1.45 | 2 | |

| HELICE | 22 | 90758-ZW1-B00 | GOVERN, 4.0 | 1 |

| BF80A • BF100A - Maintenance kit 400 h | ||||

|---|---|---|---|---|

| Category | NO | Reference | Designation | Qty |

| 1 | 06161-ZY9-000 | KIT MAINTENANCE (400 h) | 1 | |

| FILTER CARBURANT (BP) | 2 | 16910-ZY9-004 | FILTER PRESSURE | 1 |

| 3 | 16911-ZY3-010 | HIGH PRESSURE | 1 | |

| FILTER (HP) | 4 | 16073-ZY9-003 | JOINT TORIQUE | 1 |

| 5 | 12155-ZV5-000 | ANODE | 2 | |

| ANODE (INTERNAL) | 6 | 31754-ZY9-000 | REGULATOR'S JOIN | 1 |

| 7 | 91302-ZZ5-M01 | TORICAL JOIN 33X2.4 | 1 | |

Show More >>

Comprehensive Guide to Cold-Weather Boating

For passionate boaters, winter doesn’t mean the end of the season. However, boating in cold weather requires extra attention to ensure the safety of your crew and the maintenance of your boat and engine. Here’s a detailed guide to help you navigate safely and comfortably during winter.

1. Boat Maintenance and Preparation

Proper maintenance is key to protecting your boat during freezing conditions. Follow these tips to prevent cold-weather damage:

- Engine Preparation: For sterndrive or inboard engines, flush the cooling system with antifreeze before freezing conditions. Repeat this process after every use in sub-zero temperatures.

- For Outboard Motors: These are self-draining, but you should tilt the engine down after each outing to fully drain the cooling system. Keep the motor in the down position during storage.

- Engine Oil: Check your owner’s manual for the recommended oil viscosity for cold temperatures. Most synthetic oils can handle temperatures as low as 20°F (-6°C).

- Lower Unit: Replace the lower unit lubricant before freezing conditions arrive. Water in the gear case could freeze and cause cracks. Water in the lubricant may also indicate a damaged propeller shaft seal.

2. Preventing Freeze-Related Damage

- Steering Mechanisms: Keep steering tubes well-greased to avoid freezing. Test full-range motion before heading out.

- Pumps: Drain the bilge and livewell pumps after each use to prevent freeze damage. Use antifreeze for livewell systems or avoid using them in extreme cold.

- Fuel System: Fill the fuel tank to prevent condensation. Use a quality fuel stabilizer to keep ethanol-blended fuel from degrading and causing deposits in the engine.

- Batteries: Use a battery maintainer to keep batteries fully charged. Cold weather can reduce a battery’s cranking power by up to 30% at freezing temperatures.

3. Crew Safety and Comfort

Ensuring the safety and comfort of your crew is crucial during cold-weather outings:

- Dress for the Conditions: Wear layered, insulated, and waterproof clothing to protect against the wind and cold.

- Life Jackets: Always wear a life jacket. In winter, consider float coats for both warmth and flotation.

- Protect Your Eyes: Use ski or motorsport goggles to shield your eyes from freezing air.

- Prevent Slips: Frost on the deck can be slippery and hard to see. Use caution when moving around the boat.

- Spare Clothes: Carry a dry bag with warm, spare clothing in case of accidental soaking.

4. Winter Navigation Tips

- Avoid Ice: Never attempt to navigate through ice, no matter how thin it appears. Ice can damage the hull or sensors and leave you stranded.

- Plan Your Route: Many navigation aids are removed or replaced with smaller markers in winter. Check maps and stay within marked channels.

- Share a Float Plan: Let someone know your route and expected return time. Carry a personal locator beacon or EPIRB for emergencies.

- Launch Ramps: After launching, allow water to drain from the trailer before exiting the ramp to prevent ice buildup.

5. Protecting Electronics

Marine electronics like GPS plotters can be sensitive to cold. Store them in a controlled environment when not in use. If left on the boat, cover them to prevent water infiltration and freezing damage.

Conclusion

With proper preparation and precautions, boating in winter can be both safe and enjoyable. Take care of your boat, engine, and crew to make the most of the colder months on the water.

Beware of E15 Fuel: A Risk to Your Engines

New EPA policies now allow E15 fuel to be sold year-round, making it essential for boaters and powersports enthusiasts to pay close attention when refueling. Choosing the wrong fuel can damage marine, motorcycle, ATV, or UTV engines and may even void your warranty.

What is E15 Fuel?

E15 is a gasoline blend containing 15% ethanol, derived from corn or other grains. Historically, it was restricted during summer months due to its high volatility, which contributes to smog formation in hot weather. However, starting in 2022, the EPA issued waivers allowing E15 sales year-round as a response to rising fuel prices.

Why is E15 Risky for Your Engines?

While E15 may work for some road vehicles, it is not designed for most marine and recreational engines. Ethanol absorbs moisture from the air, which can lead to:

- Corrosion of metal components

- Deterioration of plastic or rubber parts

- Fuel leakage through rubber fuel lines

- Starting and operational difficulties

High ethanol levels also increase the risk of water accumulation in the fuel tank, especially during long storage periods, posing a significant threat to marine and powersports engines.

Warranty Implications

Using fuel with more than 10% ethanol (such as E15) may void your manufacturer’s warranty. Engine manufacturers have long warned about ethanol-related damage, but the increased availability of E15 heightens the risk of accidental use due to mislabeling or lack of attention at the pump.

Tips for Safe Refueling

- Always check ethanol-content labels at the pump.

- Use only fuel with 10% ethanol or less unless your manufacturer specifies otherwise.

- Take your time to read the pump information before filling your tank, even if you’re in a hurry.

Following these simple steps can save you costly repairs and extend your engine’s lifespan.

Maintenance Tips for Mercury OptiMax Outboards

Mercury® OptiMax® outboards are renowned for their power and efficiency. With regular maintenance, your OptiMax engine, especially the 3.0-liter Pro XS® models, can deliver exceptional performance for years to come.

1. Follow the Owner’s Manual

Strictly adhering to the maintenance schedule outlined in your owner’s manual is critical to avoiding costly repairs and ensuring your engine’s reliability. If you don’t have a manual, download a PDF version from Mercury Marine or order a printed copy from an authorized Mercury dealer.

2. Use the Right Oil

The manual recommends Quicksilver Synthetic Blend Performance DFI 2-Stroke oil, which is specifically formulated for OptiMax engines. This oil minimizes carbon buildup, reduces piston wear, and optimizes engine performance. Using inferior oil can cause severe engine damage.

3. Treat Your Fuel

To keep fuel injectors clean, add Quicksilver Quickleen® at every fill-up. This cleaner removes carbon deposits from injectors, spark plugs, and piston crowns. Follow the bottle’s instructions for optimal results.

4. Replace the Fuel Filter with Proper Tools

Fuel filter replacement is part of the annual or 100-hour maintenance. Use the Quicksilver Fuel Filter Tool (p.n. 91‑896661) to safely remove and replace the filter without damaging the plastic tabs. Apply engine oil or Quicksilver 2-4-C Marine Grease to the filter’s O-rings before installation.

5. Drain the Vapor Separator Tank

Follow the instructions in the manual to drain water from the Vapor Separator Tank (VST). This helps maintain engine performance and prevents moisture-related issues.

Regular Maintenance for Long-Term Enjoyment

With proper care and the right tools, your Mercury OptiMax outboard will continue to provide reliable power and performance for years of on-water enjoyment.

How to Change Oil in Your Mercury Outboard Engine: A Practical Guide

Oil is the lifeblood of your Mercury® outboard engine. Regularly changing the oil and filter after 100 hours of use or at least once a year is essential maintenance. Many boaters perform this task during winterization or before off-season storage to ensure their engine is ready for the next season.

1. Choose the Right Oil and Filter

Using the correct oil and filter as outlined in your owner’s manual is vital. Quicksilver marine oils, available in mineral, synthetic, and synthetic blend formulations, are designed to protect marine engines from wear and corrosion. Quicksilver filters ensure high-quality filtration and are built to prevent leaks or collapse.

2. Essential Tools

- Wrench or socket for drain plug

- Oil filter wrench

- Funnel

- Clean rags and gloves

- Oil pump or drain kit

- Oil catch pan

3. Draining the Oil

- Trim the outboard past vertical for one minute to drain trapped oil.

- Return the outboard to vertical and remove the cowl.

- Use a pump to extract oil through the dipstick or locate the drain plug to release oil into a catch pan.

- Tighten the drain plug and dispose of the oil properly.

4. Replacing the Filter

- Locate the oil filter (usually on the starboard side).

- Place a rag below the filter, remove it, and lubricate the new filter’s gasket.

- Thread the new filter and tighten securely.

5. Adding Fresh Oil

- Check the drain plug, add new oil with a funnel, and check the level with the dipstick.

- Idle the engine to ensure no leaks, then recheck the oil level.

Pro Tip: Check for Contaminants

Look for signs of water (milky oil) or fuel (strong odor) in your used oil. If contamination is found, consult a Mercury dealer.

By following these simple steps and using high-quality Quicksilver lubricants and filters, you’ll keep your Mercury outboard running at its best.

Show More >>

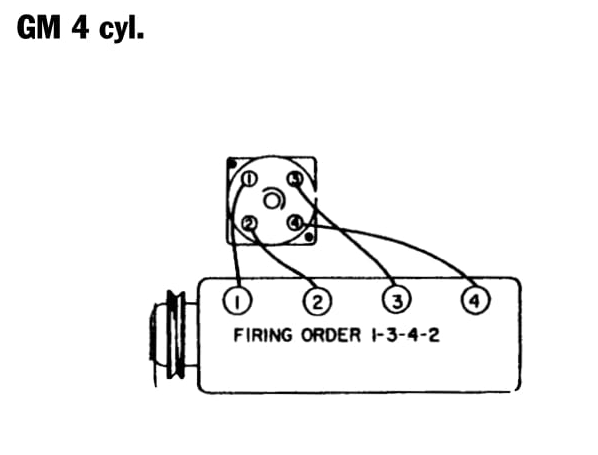

Number of cylinders: 4 cylinders

Displacement: 3L

Standard diameters

Pistons: 102.6 / Connecting rods: 53.34 / Bearings: 58.38

Tightening torque m. Kg

Cylinder head: 12.5 / Flywheel: 8.5 / Connecting rod: 4 / Bearing: 9.5

Number of cylinders: 8 cylinders

Displacement: 4.6L

Standard diameters

Pistons: 98.42 / Connecting rods: 50.8 / Bearings: 98.38

Tightening torque m. Kg

Cylinder head: 8.8 / Flywheel: 8.2 / Connecting rod: 4.5 / Bearing: 9.5

Number of cylinders: 8 cylinders

Displacement: 4.9L

Standard diameters

Pistons: 98.42 / Connecting rods: 53.34 / Bearings: 62.19

Tightening torque m. Kg

Cylinder head: 8.8 / Flywheel: 8.2 / Connecting rod: 6.2 / Bearing: 9.5

Number of cylinders: 8 cylinders

Displacement: 5L

Standard diameters

Pistons: 95 / Connecting rods: 53.34 / Bearings: 62.19

Tightening torque m. Kg

Cylinder head: 8.8 / Flywheel: 8.2 / Connecting rod: 6.2 / Bearing: 9.5

Show More >>

Number of cylinders: 8 cylinders

Displacement: 4.6L

Standard diameters

Pistons: 98.42 / Connecting rods: 50.8 / Bearings: 58.38

Tightening torque m. Kg

Cylinder head: 8.8 / Flywheel: 8.2 / Connecting rod: 4.5 / Bearing: 9.5

Number of cylinders: 8 cylinders

Displacement: 5.4L

Standard diameters

Pistons: 101.6 / Connecting rods: 53.34 / Bearings: 62.19

Tightening torque m. Kg

Cylinder head: 8.8 / Flywheel: 8.2 / Connecting rod: 6.2 / Bearing: 9.5

Number of cylinders: 8 cylinders

Displacement: 7 L

Standard diameters

Pistons: 108 / Connecting rods: 55.88 / Bearings: 69.81

Tightening torque m. Kg

Cylinder head: 10.8 / Flywheel: 6.2 / Connecting rod: 6.8 / Bearing: 10.8

Number of cylinders: 8 cylinders

Displacement: 5L

Standard diameters

Pistons: 95 / Connecting rods: 53.34 / Bearings: 62.19

Tightening torque m. Kg

Cylinder head: 8.8 / Flywheel: 8.2 / Connecting rod: 6.2 / Bearing: 9.5

Show More >>

Honda Marine BF8 Engines

| Parts | References |

|---|---|

| Oil filter | 15400-PFB-014 |

| Fuel filter | 16910-ZV4-015 |

| Spark plugs x 2 | CR5EH-9 |

| Turbine | 19210-ZW9-013 |

| Turbine seal | 19232-ZW9-000 |

| Turbine O-ring | 91301-ZG3-000 |

| Thermostat | 19300-ZW9-003 |

| Thermostat O-ring | 19317-ZW9-000 |

| Engine drain gasket | 91301-216-000 |

| Base drain gasket | 91301-ZW4-003 |

| Anode block | 12155-ZV4-A00 |

| Base anode x 2 | 41106-ZW9-000 |

Honda Marine BF10 Engines

| Parts | References |

|---|---|

| Oil filter | 15400-PFB-014 |

| Fuel filter | 16910-ZV4-015 |

| Spark plugs x 2 | CR5EH-9 |

| Turbine | 19210-ZW9-A32 |

| Turbine seal | 19232-ZW9-000 |

| Turbine O-ring | 91301-ZG3-000 |

| Thermostat | 19300-ZW9-003 |

| Thermostat O-ring | 19317-ZW9-000 |

| Engine drain gasket | 91301-216-000 |

| Base drain gasket | 91301-ZW4-003 |

| Anode block | 12155-ZV4-A00 |

| Base anode x 2 | 41106-ZW9-000 |

Honda Marine BF20 Engines

| Parts | References |

|---|---|

| Oil filter | 15400-PFB-014 |

| Fuel filter | 16910-ZV4-015 |

| Spark plugs x 2 | CR5EH-9 |

| Turbine | 19210-ZW9-A32 |

| Turbine seal | 19232-ZW9-000 |

| Turbine O-ring | 91301-ZG3-000 |

| Thermostat | 19300-ZW9-003 |

| Thermostat O-ring | 19317-ZW9-000 |

| Engine drain gasket | 90601-ZE2-000 |

| Base drain gasket | 91301-ZW4-003 |

| Base anode x 2 | 41106-ZW9-000 |

Honda Marine BF30 Engines

| Parts | References |

|---|---|

| Oil filter | 15400-PFB-014 |

| Fuel filter | 16910-ZV4-015 |

| Spark plugs x 3 | DR7EA |

| Turbine | 19210-ZV7-003 |

| Turbine O-ring | 91356-ZV5-000 |

| Turbine paper gasket | 19233-ZV5-000 |

| Thermostat | 19300-ZW9-003 |

| Thermostat O-ring | 19351-ZV5-000 |

| Engine drain gasket | 90601-ZE2-000 |

| Base drain gasket | 91301-ZW4-003 |

| Anode block | 12155-ZV5-000 |

| Drift anode | 41107-ZV5-000 |

| Base anode x 2 | 41106-ZW9-000 |

Show More >>

| BF40D • BF50D - 200 h maintenance kit | ||||

|---|---|---|---|---|

| Category | NO | Reference | Designation | Qty |

| 1 | 06510-ZZ5-000 | KIT MAINTENANCE (200 h) | 1 | |

| VIDANGE MOTOR | 2 | 15400-ZZ3-003 | OIL FILTER CARTON (DENSO) | 1 |

| 3 | 90601-ZE2-000 | RONDELLE VIDANGE, 12MM | 1 | |

| BREAKDOWN CIRCUIT | 4 | 19300-ZW9-003 | HERMOSTAT | 1 |

| 5 | 19351-ZV5-000 | JOINT COVERED THEHERMOSTAT | 1 | |

| 6 | 1921-ZV5-003 | TURBINE | 1 | |

| 7 | 19231-ZV5-000 | TURBINE PLACTURE | 1 | |

| 8 | 19233-ZV5-000 | JOINT TURBINE B | 1 | |

| 9 | 1923-ZV5-000 | POMP BODY | 1 | |

| 10 | 90752-ZV5-003 | CLAVETTE | 1 | |

| 11 | 91356-ZV5-000 | TORICAL JOIN POMPE | 1 | |

| ANODE (EXTERNAL) | 12 | 06411-ZV5-020 | ANODE | 1 |

| 13 | 41106-ZW9-000 | ANODE | 2 | |

| 14 | 90205-ZY1-000 | ECROU FREIN, 6MM | 1 | |

| 15 | 90205-HW1-670 | EPAULE VIS, 6X25 | 1 | |

| VIDANGE EMBASE | 16 | 90101-ZW9-003 | MONITORING | 1 |

| 17 | 90120-ZY3-000 | VIDANGE VIS | 1 | |

| 18 | 91301-ZW4-003 | JOINT TORIC, 6.9X1.45 | 2 | |

| HELICE | 19 | 90758-ZV5-000 | GOVERNING, 4.0 | 1 |

| BF60A • BFP60A - 200 h maintenance kit | |||||

|---|---|---|---|---|---|

| Category | NO | Reference | Designation | BF | BFP |

| 1 | 06510-ZZ3-000 | KIT MAINTENANCE (200 h) | 1 | ||

| 1 | 06510-ZZ3-800 | KIT MAINTENANCE (200 h) | 1 | ||

| VIDANGE MOTOR | 2 | 15400-ZZ3-003 | OIL FILTER CARTON (DENSO) | 1 | 1 |

| 3 | 90601-ZE2-000 | VIDANGE ROUND, 12MM | 1 | 1 | |

| REFRIDING CIRCUIT | 4 | 19300-ZW9-003 | HERMOSTAT | 1 | 1 |

| 5 | 19317-ZW9-000 | JOINT TORIQUE, COVER COVER OF THERMOSTAT | 1 | 1 | |

| 6 | 1921-ZV5-003 | TURBINE | 1 | 1 | |

| 7 | 1931-ZZ3-000 | POMP PLACTURE | 1 | 1 | |

| 8 | 1934-ZZ3-000 | PLAQUE JOIN | 1 | ||

| 9 | 1934-ZZ3-E00 | PLAQUE JOIN | 1 | ||

| 10 | 1923-ZZ3-000 | POMP BODY | 1 | 1 | |

| 11 | 90752-ZV5-003 | CLAVETTE | 1 | 1 | |

| 12 | 90756-ZV5-000 | CENTRAL PION, 6X10 | 2 | 2 | |

| 13 | 91356-ZZ3-000 | JOINT TORIQUE | 1 | 1 | |

| NODE (EXTERNAL) | 14 | 06411-ZV5-020 | ANODE | 1 | 1 |

| 15 | 41109-ZW1-B00 | ANODE | 2 | 2 | |

| 16 | 90205-ZY1-000 | ECRO-FREIN, 6MM | 1 | 1 | |

| 17 | 90206-HW1-671 | EPAULATED VISES, 6X30 | 1 | 1 | |

| VIDANGE EMBASE | 18 | 90101-ZW9-003 | CONTROL VISIT | 1 | 1 |

| 19 | 90120-ZY3-000 | VIDANGING VISIT | 1 | 1 | |

| 20 | 91301-ZW4-003 | JOINT TORIC, 6.9X1.45 | 2 | 2 | |

| HELICE | 21 | 90758-ZV5-000 | GOVERN, 4.0 | 1 | |

| 22 | 90758-ZW1-B00 | GOVERN, 4.0 | 1 | ||

tse

Number of cylinders: 6 cylinders

Displacement: 4.3 L

Standard diameters

Pistons: 101.6 / Connecting rods: 57.14 / Bearings: 62.19

Tightening torque m. Kg

Cylinder head: 8.8 / Flywheel: 8.2 / Connecting rod: 6.2 / Bearing: 9.5

Nombre de cylindres : 4 cylindres

Cylindrée : 2.5L

Diamètres standards

Pistons : 98.42 / Bielles : 50.8 / Paliers : 58.38

Couple de serrage m. Kg

Culasse : 12.5 à 13.8 / Volant : 8.2 à 8.8 / Bielle : 4 à 4.5 / Palier : 8.2 à 9.5

Number of cylinders: 6 cylinders

Displacement: 4L

Standard diameters

Pistons: 98.42 / Connecting rods: 50.8 to 53.34 / Bearings: 58.38

Tightening torque m. Kg

Cylinder head: 12.5 to 13.8 / Flywheel: 8.2 to 8.8 / Connecting rod: 4 to 4.5 / Bearing: 8.2 to 9.5

Show More >>

Moteurs Mercruiser 2,5 CH - 3,5 CH - 4 TEMPS

| Pièces | Références |

|---|---|

| Allumage | Bougie803507 Corde de lanceur8M0160482 |

| Anode | Anode823913Q |

| Carburation | Kit de réparation de carburateur8M0090764 |

| Filtration | Filtre à essence8M0157133 |

| Hélices | Goupille hélice95295 |

| Joints |

|

| Kit d'entretien | Kit d'entretien aux 100 heures8M0181314 |

| Refroidissement |

Moteurs Mercruiser 4-5-6 CH 4 TEMPS

| Pièces | Références |

|---|---|

| Allumage | |

| Anode | |

| Carburation | Kit de réparation de carburateur8M0044575 |

| Filtration | Filtre à essence8M0157133 |

| Hélices | Goupille hélice815026 |

| Joints | |

| Kit d'entretien |

|

| Refroidissement |

Moteurs Mercruiser 8-9,9 CH 4 TEMPS

| Pièces | Références |

|---|---|

| Allumage |

|

| Anode |

|

| Carburation | |

| Courroie | |

| Filtration | Filtre à essence8M0157133 |

| Joints |

|

| Kit d'entretien |

|

| Refroidissement |

Moteurs Mercruiser 8-9,9 CH 4 TEMPS

| Pièces | Références |

|---|---|

| Allumage |

|

| Anode |

|

| Carburation | |

| Courroie | |

| Filtration | Filtre à essence8M0157133 |

| Joints |

|

| Kit d'entretien |

|

| Refroidissement |

Mercruiser 15 HP Carb - 4 STROKE engines

| Parts | References |

|---|---|

| Ignition : |

|

| Anode : | |

| Carburettor : | |

| Filtration : | |

| Seals : | |

| Service kit : |

|

| Cooling system : |

Mercruiser 15-20 CH EFI engines

| Parts | References |

|---|---|

| Ignition : |

|

| Anode : | |

| Filtration : | |

| Seals : |

|

| Service kit : |

|

| Cooling system : |

|

Mercruiser 40 - 50 - 60 CH EFI (4 Cylinders) CT engines

| Parts | References |

|---|---|

| Ignition : | |

| Anode : | |

| Belt : | |

| Drift : | |

| Filtration : | |

| Gaskets: | |

| Service kit : | |

| Cooling system : |

|

Mercruiser 25 - 30 HP - 4 STROKE engines

| Parts | References |

|---|---|

| Ignition : |

|

| Anode : | |

| Filtration : | |

| Seals : |

|

| Service kit : |

|

| Cooling system : |

Mercruiser 40 CH EFI engines (3 Cylinders)

| Parts | References |

|---|---|

| Ignition : | |

| Anode : | |

| Drift : | |

| Filtration : |

|

| Seals : |

|

| Cooling : |

Show More >>

Number of cylinders: 4 cylinders

Displacement: 2.5L

Standard diameters

Pistons: 98.42 / Connecting rods: 50.8 / Bearings: 58.38

Tightening torque m. Kg

Cylinder head: 12.5 to 13.8 / Flywheel: 8.2 to 8.8 / Connecting rod: 4 to 4.5 / Bearing: 8.2 to 9.5

Nombre de cylindres : 8 cylindres

Cylindrée : 5 L

Diamètres standards

Pistons : 95 / Bielles : 53.34 / Paliers : 62.19

Couple de serrage m. Kg

Culasse : 8.8 / Volant : 8.2/ Bielle : 6.2 / Palier : 9.5

Nombre de cylindres : 6 cylindres

Cylindrée : 4L

Diamètres standards

Pistons : 98.42 / Bielles : 50.8 à 53.34 / Paliers : 58.38

Couple de serrage m. Kg

Culasse : 12.5 à 13.8 / Volant : 8.2 à 8.8 / Bielle : 4 à 4.5 / Palier : 8.2 à 9.5

Nombre de cylindres : 4 cylindres

Cylindrée : 3L

Diamètres standards

Pistons : 101.6 / Bielles : 53.34 / Paliers : 58.38

Couple de serrage m. Kg

Culasse : 12.5 à 13.8 / Volant : 8.2 à 8.8 / Bielle : 4 à 4.5 / Palier : 8.2 à 9.5

Show More >>

Test

PCM H5/H6 5.3L/6.2L engines

| Parts | References |

|---|---|

| Inboard engine oil 5W30 | Ref. RX530-5 |

| OEM long PCM oil filter | Ref. R077001 |

| Spark plugs | Ref. 41/110 (x8) |

| Spark plug wire kit | Ref. RK120026 |

| Flame arrester | Ref. R145029 |

| Serpentine belt | Ref. R066040 |

| Cooling turbine | Ref. RP061022 |

| OEM fuel filter | Ref. RP080026 |

| HP fuel filter | Ref. R077019 |

| Thermostat kit | Ref. RF026010-02A |

PCM Engines Excalibur 330 / 343

| Parts | References |

|---|---|

| MOTOR OIL 15W40 T4 - 1GL | Ref. RX1540LF (x2) |

| Oil filter PCM long OEM | Ref. R077001 |

| CONTACT MERCRUISER | Ref. 27/91892 |

| 100 PSI OIL PRESSURE | Ref. R020049 |

| KIT FILS GM V8 MPI | Ref. F813 |

| KIT FILS OF BOUGIES PCM 5.7 CATALYSIS | Ref. RK120023 |

| V8 MPI DISTRIBUTOR | Ref. AP3093 |

| ROTOR V6-V8 MPI | Ref. AP3094 |

| COMPLETE ALLUMING BOBINE MPI | Ref. AP8000 |

| TURBINE REFRIDING SHERWOOD OEM | Ref. SHE10615K |

| TURBINE REMOVAL GM PCM ( SERPENTINE ) | Ref. RP061022 |

| FILTER A ESSENCE PCM OEM | Ref. RP080026 |

| UNIVERSAL ELECTRIC GASILE POMP 12V ( 330 ) | Ref. P4070 |

| ELECTRIC TEST POMP PCM ( 330 - 343 ) | Ref. RA080025A |

| ELECTRIC TEST POMP BP PCM ( 343 ) | Ref. RA080036 |

| THERMOSTAT PCM - 160° | Ref. R026002 |

| THERMOSTAT - 170° ( ECHANGEUR ) | Ref. R026007 |

| CONTACT CARTER THERMOSTAT PCM | Ref. RM0258 |

| GM V6-V8 BRAKING POMPE | Ref. W898 |

| KNOCK SENSOR | Ref. AP6039 |

| PLASTICAL POSITION CAPTOR | Ref. AP3604 |

| DAMPER GM 203MM - 4.8KG | Ref. TE33306 |

| REGULATOR MPI ESSENCE | Ref. 885174 |

| INJECTOR MPI 3 VIS BEFORE 2007 | Ref. AP9402 |

| INJECTOR MPI 4 VIS AFTER 2007 | Ref. AP9403 |

| MPI/EFI TEMPERATURE FUND | Ref. 18/7600 |

| OIL PRESSURE - 80PSI | Ref. 700433 |

| COMPLETE PCM POTENTIOMETER | Ref. R119005A |

| SEA WATER POMP EXCALIBUR PCM 343 | Ref. RA057034 |

| SEA WATER POMPE SHERWOOD PCM 330 | Ref. RA057026 |

| SEA WATER POMPE SHERWOOD PCM 330 | Ref. P1014 |

| ALTERNATOR 12V 70AMP PCM 330 | Ref. ARC20825 |

| GM MARRIER 4-6-8CYL DECALE | Ref. DR51150 |

| UNIVERSAL INVERSEUR V8 | Ref. ARC30459 |

| COUD EXCHANGE PCM GM-FORD OEM NO CATA | Ref. PCM29011 |

| COUD JOIN EXCHANGE PCM FORD - GM NO CATA | Ref. RM002 |

| COLLECTOR EXCHANGE PCM GM V8 OEM | Ref. PCM28009 |

| KIT JOINTS COLLECTOR EXCHANGE V8 SB | Ref. FP17420 |

| COLLECTOR EXCHANGE CATALYSE PCM SB - BABORD | Ref. R028025 |

| COLLECTOR EXCHANGE CATALYSE PCM SB - TRIBORD | Ref. R028026 |

| FILTER CATALYSEUR COLLECTOR PCM EXCHANGE | Ref. R144004A |

| FILTER SUPPORT CATALYSEUR PCM | Ref. RM0291 |

| COUD JOIN EXCHANGE CATALYSE PCM CATANIUM | Ref. RM0285 |

| COUD JOIN EXCHANGE CATALYSE PCM METAL | Ref. RM0286 |

| OXYGEN SOUND CATALYSIS | Ref. AP7006 |

| ALSO INVERSEUR VELVET 262/305/350 | Ref. AS4K2C |

| ACCOUPLEMENT INVERSEUR PCM 1.23 | Ref. R140020 |

| ACCOUPLY INVERSEUR HURTH - ZF | Ref. R140019 |

Ford GT 40 engines

| Parts | References |

|---|---|

| INBOARD MOTOR OIL 15W40 - 5L | Ref. RX1540-5 (x2) |

| OIL FILTER PCM LONG OEM | Ref. R077001 |

| BOUGIE AUTOLITE FORD GT40 | Ref. 764 |

| TURBINE REFRIDING SHERWOOD OEM | Ref. SHE0995K |

| KIT COURROIES PCM FORD OEM | Ref. RP066001/8 |

| FILTER A ESSENCE PCM OEM | Ref. RP080026 |

| HP PCM OEM ESSENCE FILTER | Ref. R077019 |

| KIT THERMOSTAT PCM 160F AND JOINTS | Ref. RP026002 |

| BRAKING POMPE V8 FORD | Ref. W1028 |

| COLLECTOR EXCHANGE PCM FORD V8 OEM | Ref. PCM28001 |

| COUD EXCHANGE V8 PCM FORD OEM SHORT | Ref. PCM29001 |

| COUD EXCHANGE PCM GM-FORD OEM LONG | Ref. PCM29011 |

| COUD JOIN EXCHANGE PCM FORD - GM | Ref. RM002 |

| KIT JOINTS COLLECTOR EXCHANGE FORTH V8 | Ref. FP17460 |

| ALTERNATOR 12V 55AMP | Ref. TE39200 |

| OIL PRESSURE DP | Ref. R020006 |

| OIL PRESSURE - 80PSI | Ref. 700433 |

| ALARMA SOUND | Ref. PS12 |

| MARRIER FORORD V8 LH | Ref. ARC70125 |

Show More >>

Moteurs Suzuki DF2 / DF2.5 (2006-2011)

| Pièces | Références |

|---|---|

| Référence du kit : | 17400-97820-000 |

| Joint de vidange d'embase | 09168-10022-000 |

| Goupille : | 09204-02001-000 |

| Joint corps de pompe | 09280-33005-000 |

| Bougie | 09482-00406-000 |

| Panneau |

|

| Turbine de refroidissement : | 17461-97JM0-000 |

| Anode aluminium ronde : | |

| Joint de vidange : |

Moteurs Suzuki DF2 / DF2.5 (2012)

| Pièces | Références |

|---|---|

| Référence du kit : | 17400-97820-000 |

| Joint de vidange d'embase | |

| Goupille : | 09202-02006-000 09204-02003-000 |

| Joint corps de pompe : | 09280-33005-000 |

| Bougie : | 09482-00406-000 |

| Plaque de pompe : |

|

| Joint sous plaque de pompe à eau : | |

| Turbine de refroidissement : | |

| Anode aluminium ronde : | |

| Joint de vidange : | 59178-97J00-000 |

Moteurs Suzuki DF4 / DF5 / DF6 (2002 - 2010)

| Pièces | Références |

|---|---|

| Référence du kit : | |

| Joint de vidange d'embase : | |

| Goupille : | 09204-03003-000 |

| Courroie : | |

| Filtre à essence : | 15410-98500-000 |

| Plaque de pompe à eau : | |

| Bague de pompe à eau : | |

| Anode aluminium ronde : |

Moteurs Suzuki DF4 / DF5 / DF6 (2011-2016)

| Pièces | Références |

|---|---|

| Référence du kit : | |

| Joint de vidange d'embase | |

| Goupille : | |

| Bougie : | |

| Filtre à essence : | 15410-98500-000 |

| Plaque de pompe à eau : | |

| Bague de pompe à eau : | |

| Anode aluminium ronde : |

Moteurs Suzuki DF8A / DF9.9A (2010-)

| Pièces | Références |

|---|---|

| Kit de pompe à eau | |

| Joint de vidange d'embase | |

| Joint de filtre à huile | |

| Joint torique anode | |

| Joint de filtre à huile | |

| Bougie | 09482-00528-000 |

| Filtre à essence | |

| Filtre à huile | |

| Cuvette inox suzuki | |

| Anode aluminium ronde | |

| Joint de vidange |

Suzuki DF9.9 / DF15 engines (2011 - 2013)

| Parts | References |

|---|---|

| Water pump kit | |

| Base drain gasket | |

| Block drain gasket | |

| Pin |

|

| Suzuki O-ring | |

| Spark plug | |

| Fuel filter | |

| Oil filter | |

| Stainless steel suzuki bowl | |

| Suzuki anode plate | |

| Drive head anode : |

Suzuki DF9.9B / DF15A / DF20A engines (2013-2017)

| Parts | References |

|---|---|

| Suzuki service kit | |

| Water pump kit | |

| Base drain gasket | |

| Pin |

|

| Oil filter gasket | |

| Spark plug | |

| Fuel filter | |

| Oil filter | |

| Stainless steel suzuki bowl | |

| Round aluminium anode : | |

| Suzuki drain gasket : |

Suzuki DF20 / DF25 V2 Engines (2006-)

| Parts | References |

|---|---|

| Water pump kit | |

| Base drain gasket | |

| Pin | |

| Suzuki O-ring | |

| Anode O-ring | |

| Spark plug | |

| Fuel filter | |

| Oil filter | |

| Pump body tank : | |

| Round aluminium anode : | |

| Motor head anode |

Suzuki DF25 / DF30 engines (2001-2010)

| Parts | References |

|---|---|

| Water pump kit | |

| Base drain gasket | |

| Engine drain gasket | |

| Pin | |

| Spark plug | |

| Suzuki anode gasket | |

| Fuel filter | |

| Oil filter | |

| Round aluminium anode : |

Suzuki DF25A / DF30A engines (2015-)

| Parts | References |

|---|---|

| Suzuki DF25A service kit | |

| Block drain gasket | |

| Pin | |

| Anode O-ring | |

| Spark plug | |

| Fuel filter | |

| Oil filter | |

| Water pump ring |

|

| Round aluminium anode : | |

| Suzuki drain gasket |

Show More >>

| Référence | Kit de Service | Filtre à Carburant | Filtre à Huile | Courroie | Impeller + Joints |

|---|---|---|---|---|---|

| STM9530 | Kit de service M2.05 | STM3690 | STM0051 | STM3669 (9,5x710mm) | STM8076 |

| STM9531 | Kit de service M2/M3 | STM3690 | STM0051 | STM7439 (75 Amp.) | STM8076 |

| STM9531X | Kit de service M2/M3 (hors M3.09) | STM3690 | STM0051 | STM6263 (40 Amp.) | STM8076 |

| STM9531Z | Kit de service M3.09 | STM3690 | STM0051 | STM7369 (40A AV10 La 910) | STM8076 |

| STM9532 | Kit de service M3.10 | STM3690 | STM0051 | STM1656 | STM8076 |

| STM9533 | Kit de service M4.14 | STM3690 | STM0051 | STM1661 | STM8076 |

| STM9543 | Kit de service M4.15-M4.17 | STM3690 | STM0051 | STM7966 | STM8076 |

| STM9545 | Kit de service M4.35/M4.45 | STM3690 | STM0051 | STM9857 (10X1090) | STM8076 |

| STM9471 | Kit de service M4.55 | STM3690 | STM0051 | STM7643 (12V-95A-1P) | STM7464 |

| STM9549 | Kit de service M4.56 (type 40) | STM3690 | STM0051 | STM7643 (12V-95A-1P) | STM8074 |

| STM9570 | Kit de service VH4.65/4.80 | STM3690 | STM4910 | STM4509 | STM8074 |

| STM9536 | Kit de service D(T)4.29 | VD60092 | VD20290 | STM6023 | STM8811 |

| STM9538 | Kit de service DT(A)43 | VD60092 | VD20262 | STM4523 | STM8250 |

| STM9544 | Kit de service DT(A)44 | VD60210 | VD20262 | STM9725 | STM8250 |

| STM9539 | Kit de service DT(A)64 | VD60092 | VD20263 | STM4523 | STM8250 |

| STM9540 | Kit de service DT(A)66 | VD60210 | VD20263 | STM9725 | STM8250 |

| STM9542 | Kit de service DT(A)67 | VD60210 | VD20263 | STM8533 | STM8250 |

| STM9568 | Kit de service VD4.120/VD4.140 | 18-14330 | VD20262 | 16-4258 | DM10021 |

| STM9569 | Kit de service VD6.170/VD6.210 | 17-8509 | VD20263 | 16-4258 | DM10021 |

| STM9574 | Kit de service VF4.140/VF4.170/VF4.190 | STM9451 | STM9452 | VFP01354 (anode) | VP000351 |

| STM9575 | Kit de service VF5.220/VF5.250 | STM9451 | STM9452 | VFP01354 (anode) | VP000351 |

| STM9567 | Kit de service VF4.145/VF4.180/VF4.200 | STM9451 | VP000313 | VFP01354 (anode) | VP000351 |

Number of cylinders: 4 cylinders

Displacement: 2L

Standard diameters

Pistons: 88.9 / Connecting rods: 54.089 / Bearings: 63.441

Tightening torque m. Kg

Cylinder head: 9 / Flywheel: 5 / Connecting rod: 5.5 / Bearing: 12.5

Number of cylinders: 6 cylinders

Displacement: 3.8L

Standard diameters

Pistons: 95 / Connecting rods: 53.34 / Bearings: 62.19

Tightening torque m. Kg

Cylinder head: 8.8 / Flywheel: 8.2 / Connecting rod: 6.2 / Bearing: 9.5

Number of cylinders: 6 cylinders

Displacement: 3L

Standard diameters

Pistons: 88.90 / Connecting rods: 54.089 / Bearings: 63.441

Tightening torque m. Kg

Cylinder head: 9 / Flywheel: 5 / Connecting rod: 5.5 / Bearing: 12.5

Number of cylinders: 6 cylinders

Displacement: 4.3L

Standard diameters

Pistons: 101.6 / Connecting rods: 57.14 / Bearings: 62.19

Tightening torque m. Kg

Cylinder head: 8.8 / Flywheel: 8.2 / Connecting rod: 6.2 / Bearing: 9.5

Show More >>

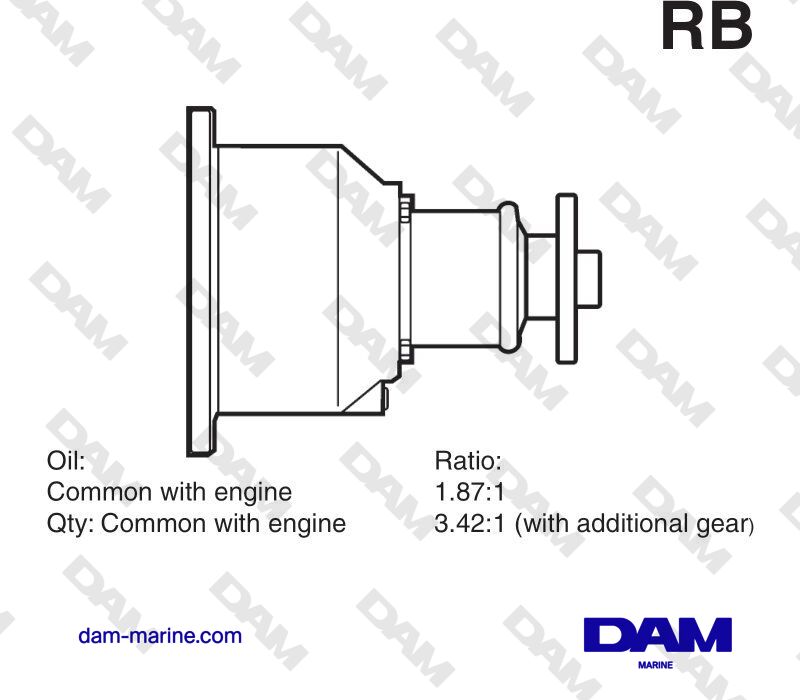

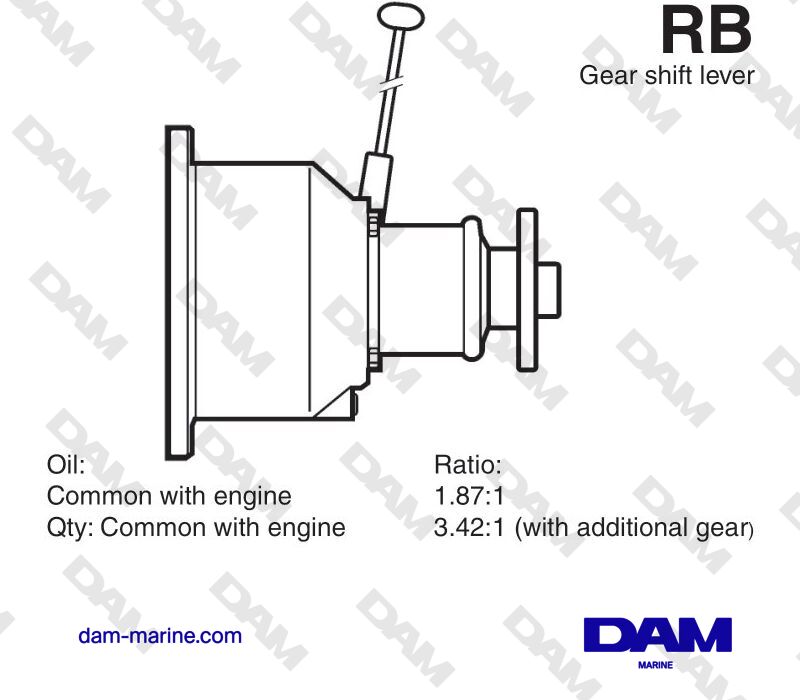

RB

RB (with lever)

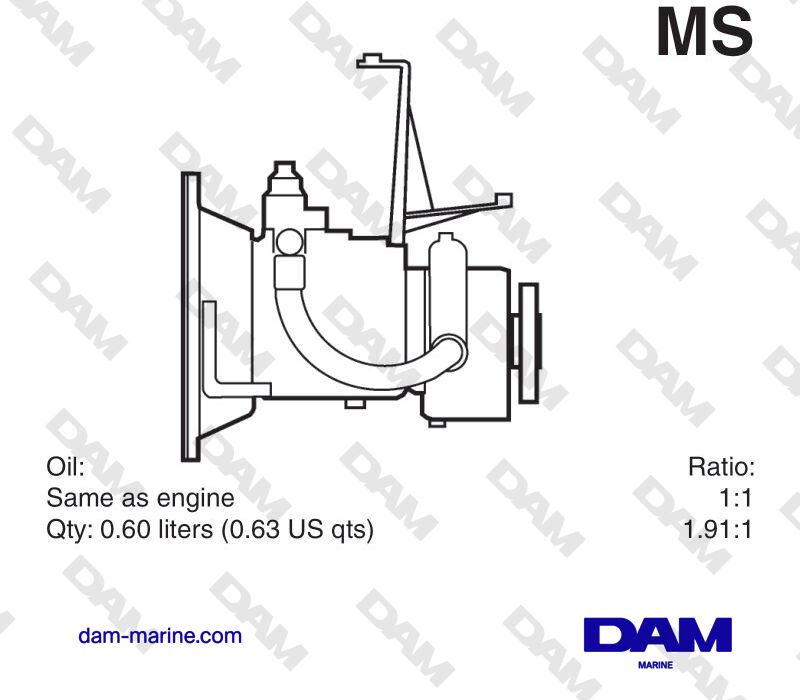

MS

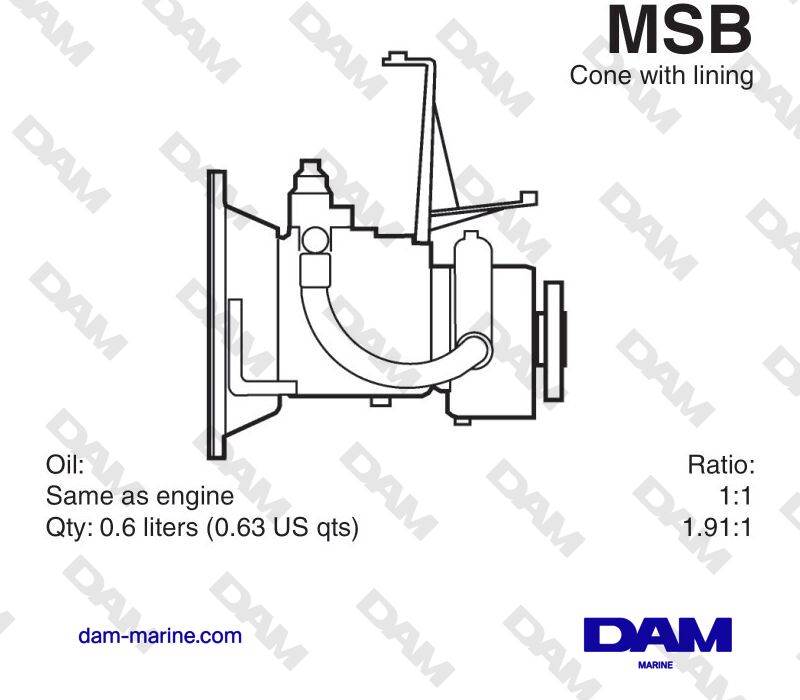

MSB

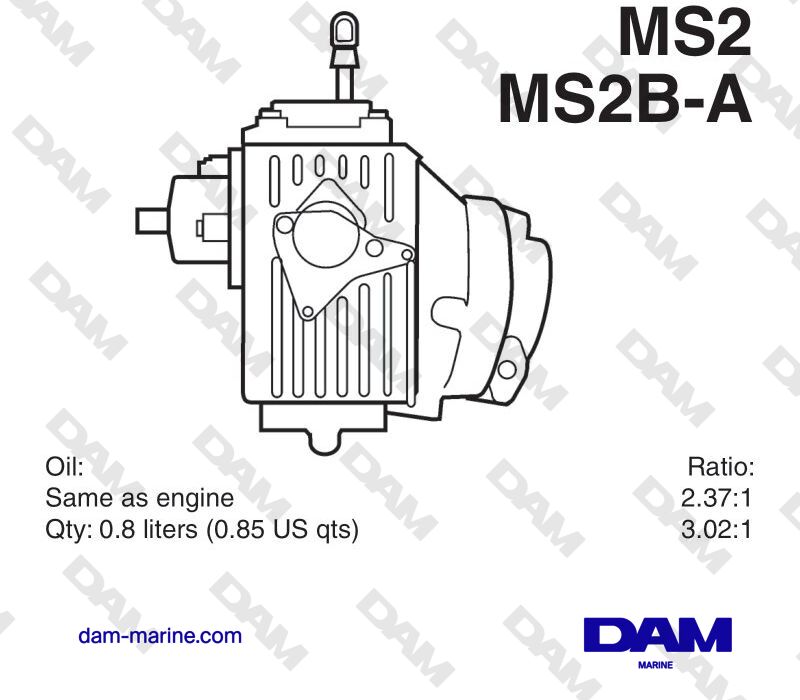

MS2 / MS2B-A

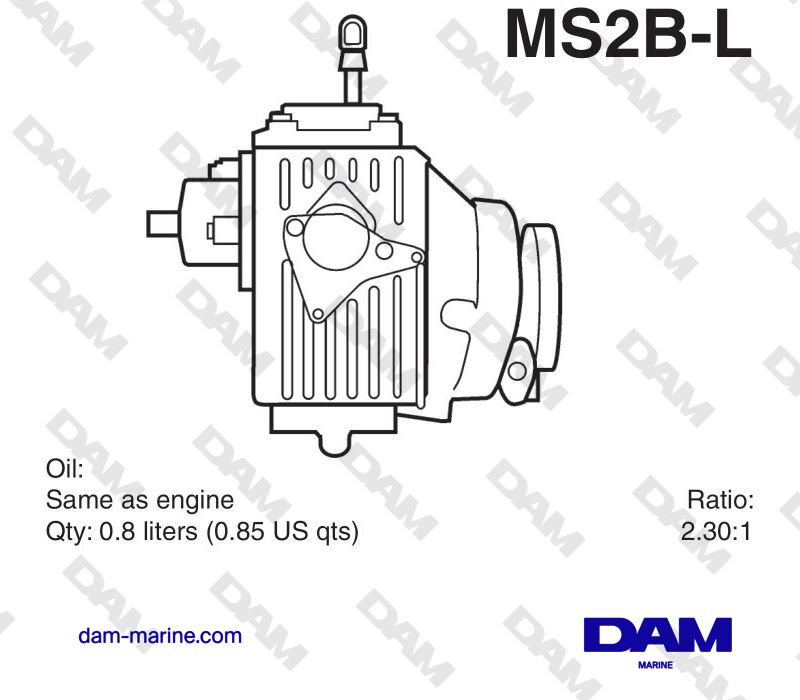

MS2B-L

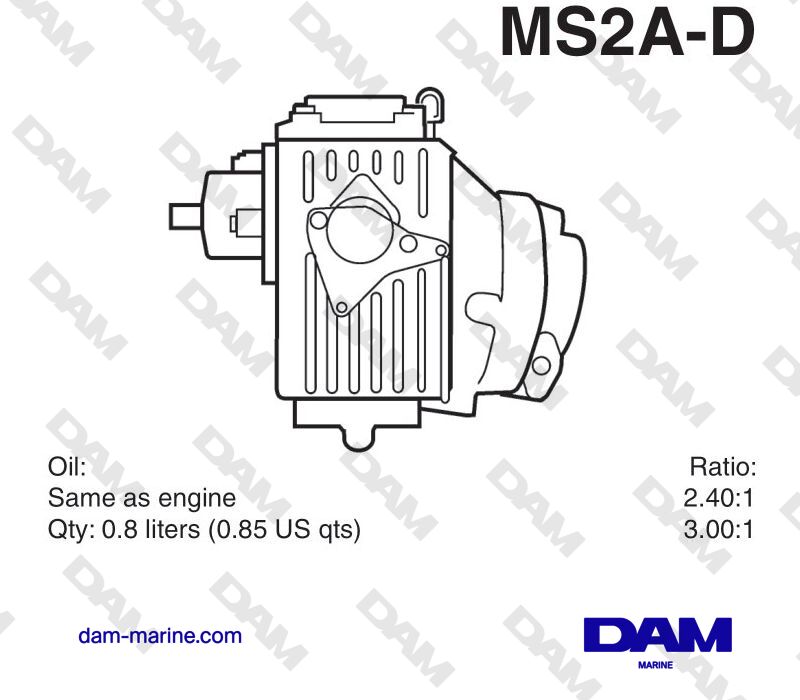

MS2A-D

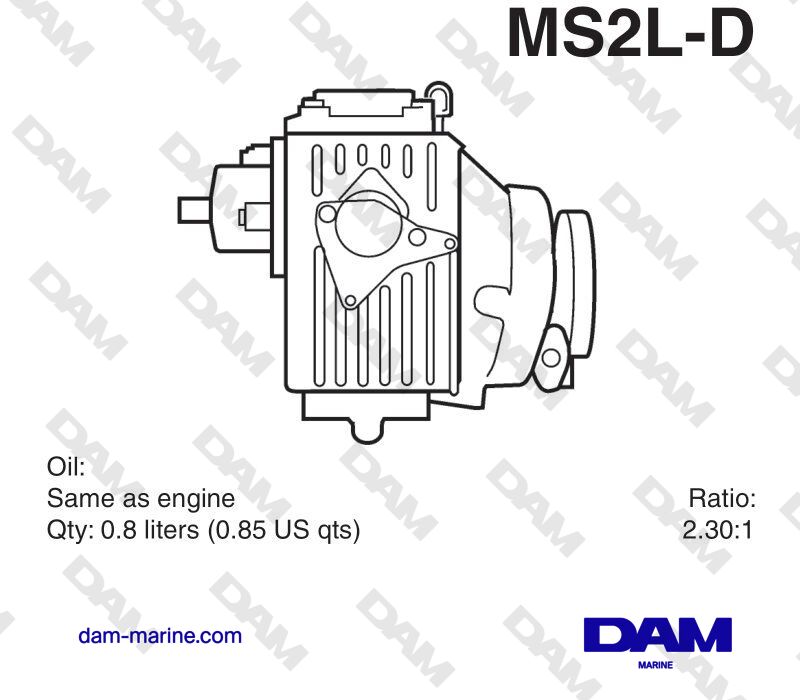

MS2L-D

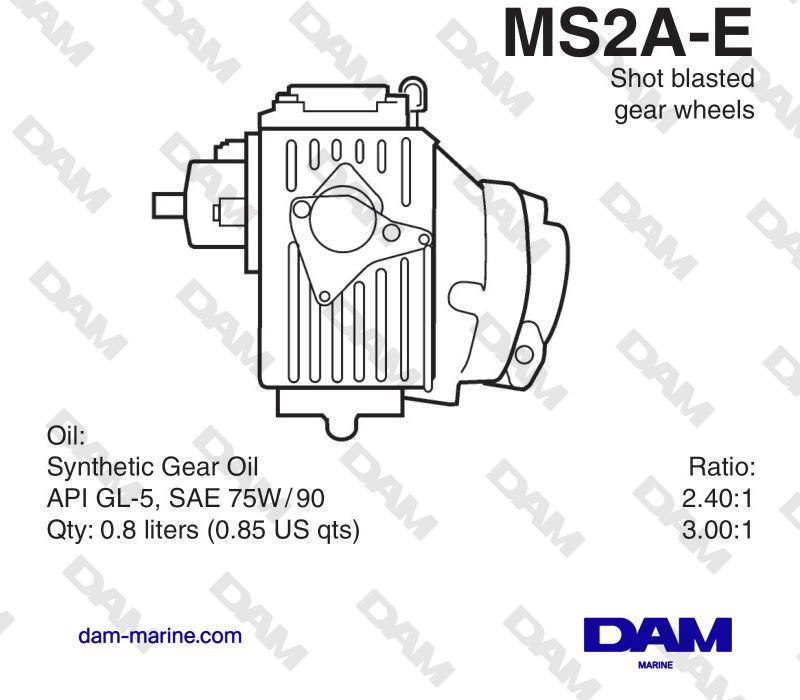

MS2A-E

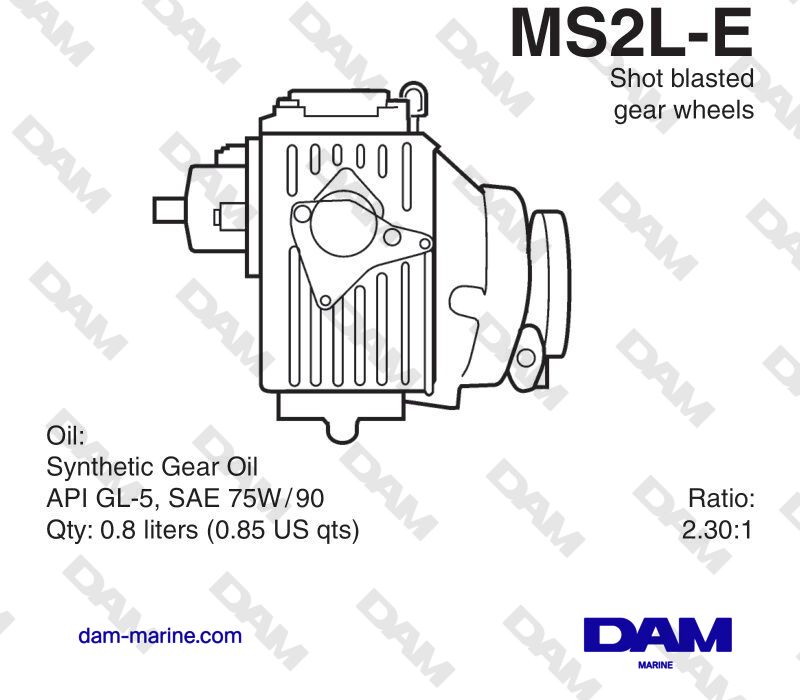

MS2L-E

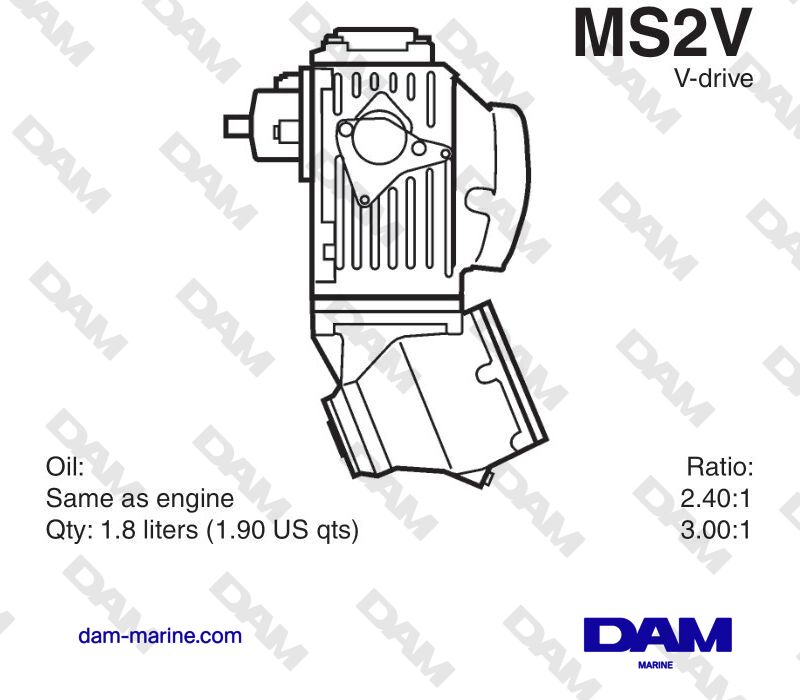

MS2V (V-Drive)

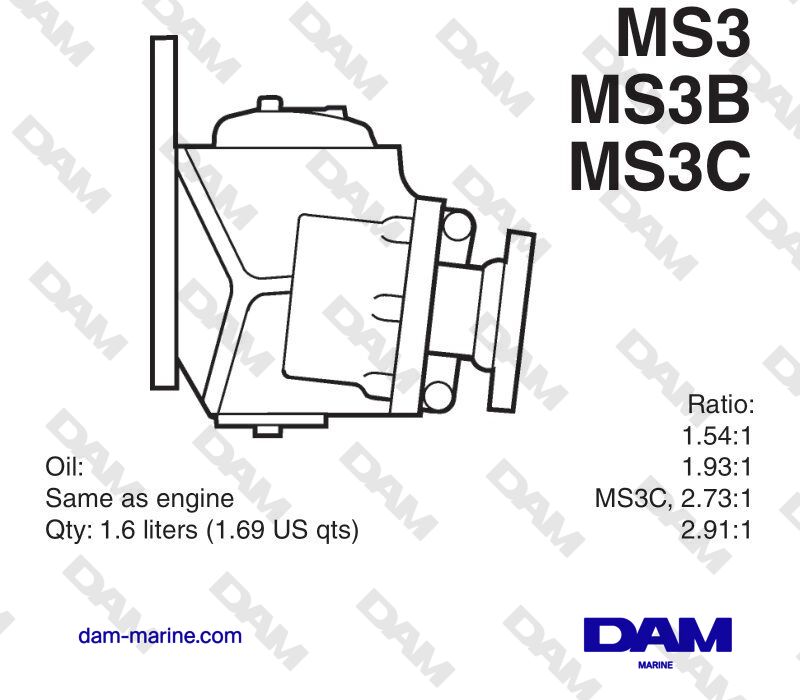

MS3 / MS3B / MS3C

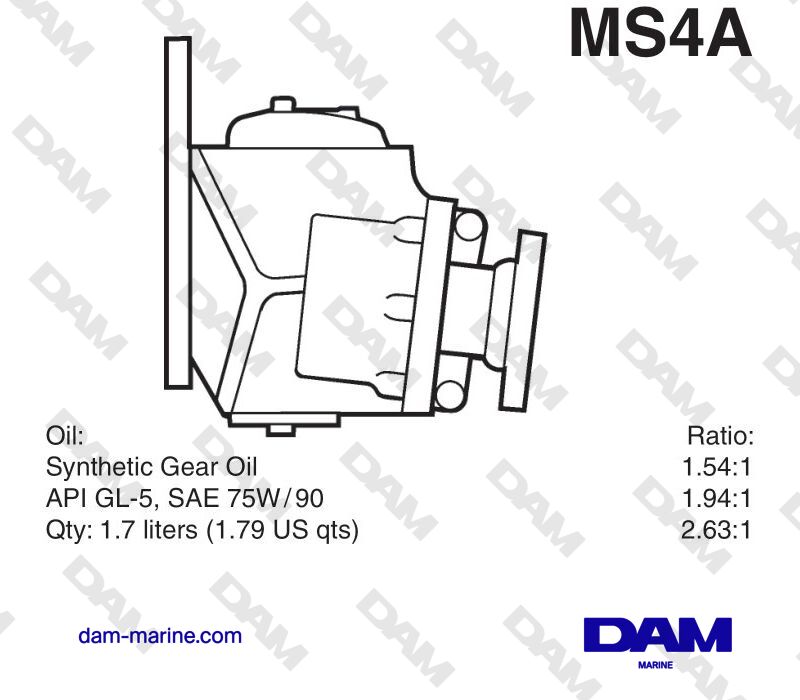

MS4A

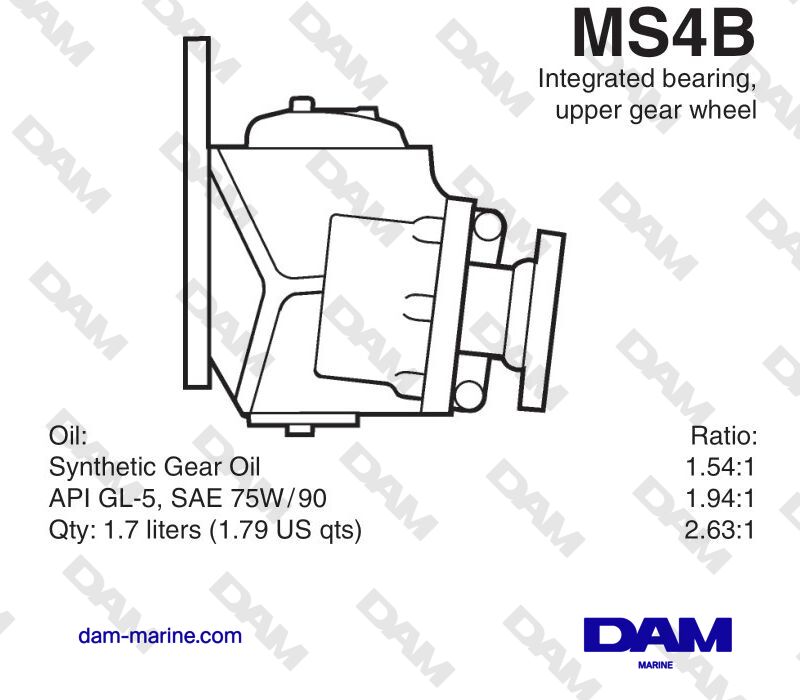

MS4B

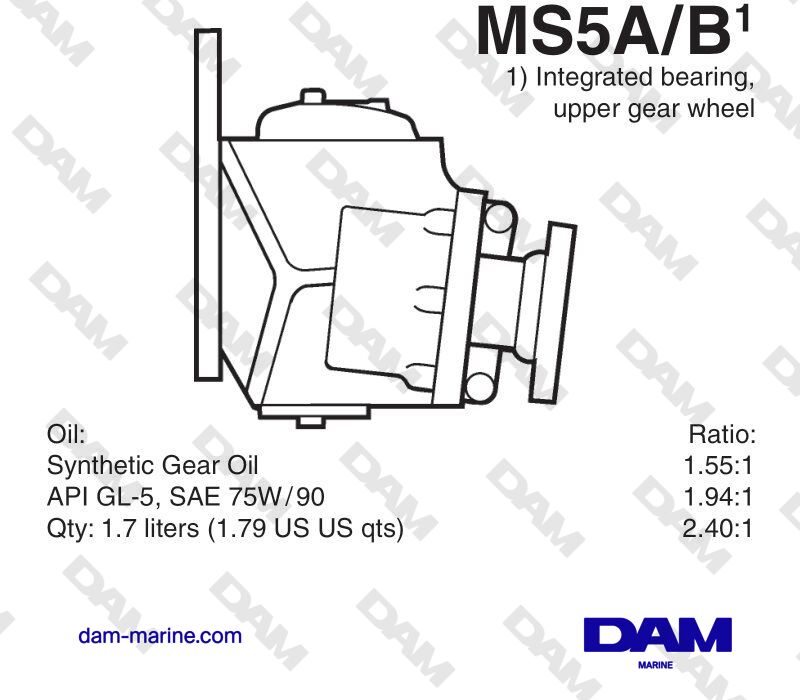

MS5A/B

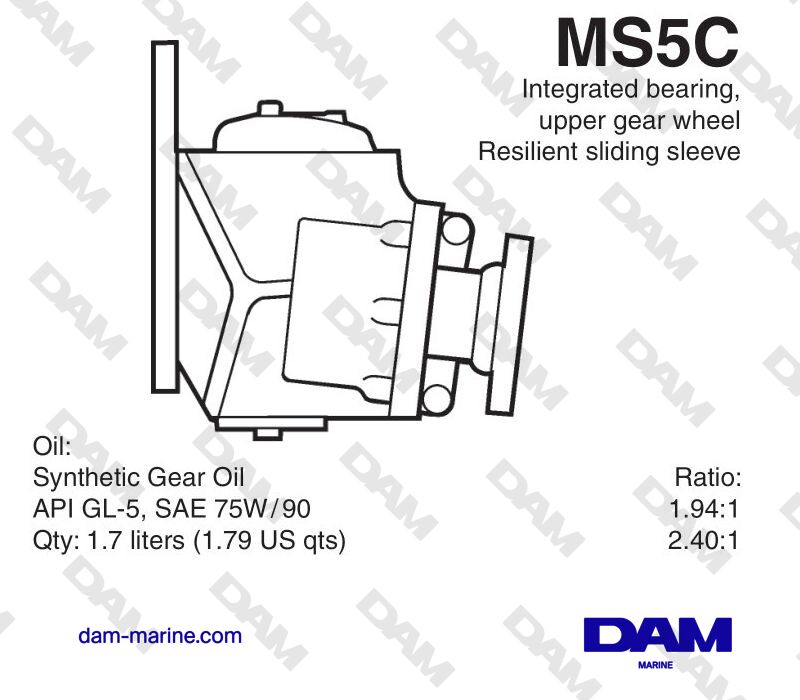

MS5C

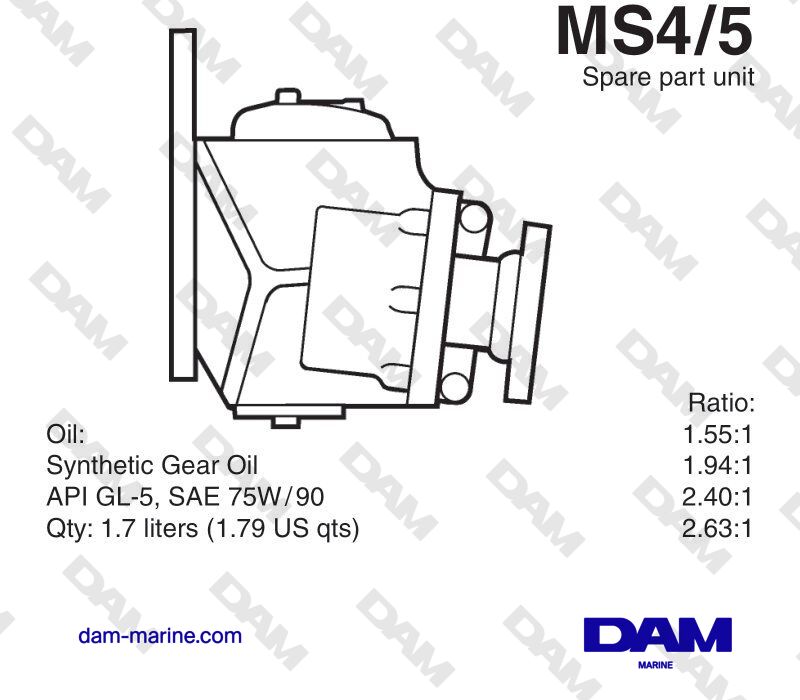

MS4/5

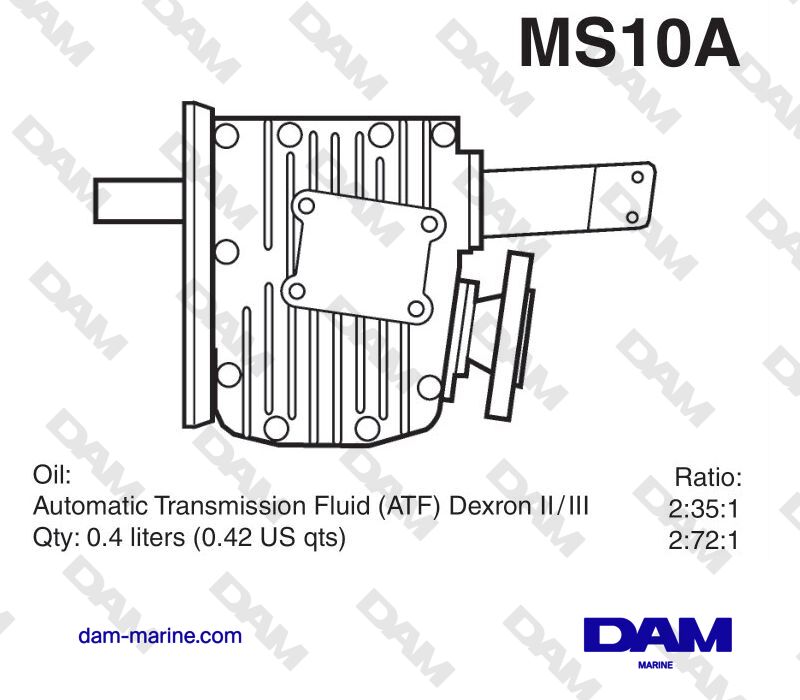

MS10A

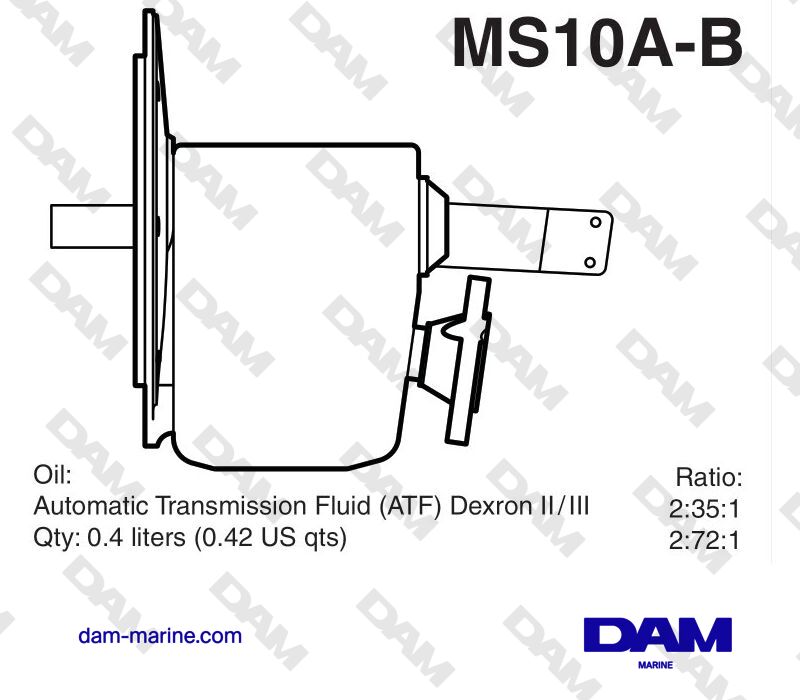

MS10A-B

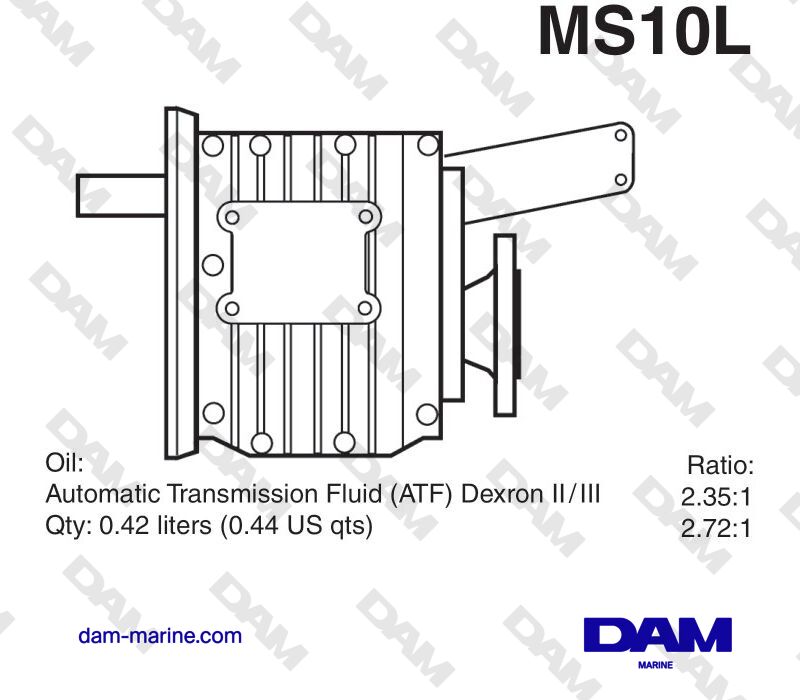

MS10L

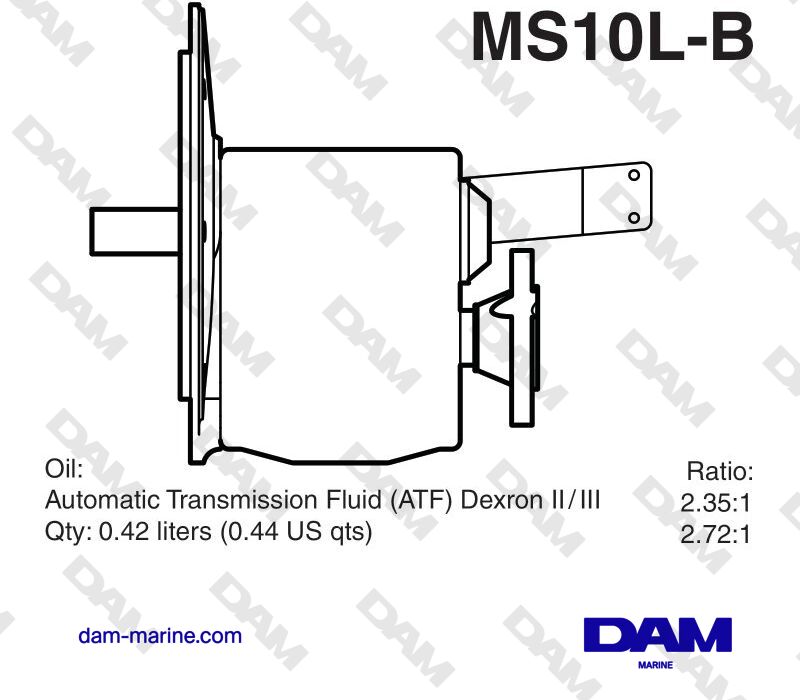

MS10L-B

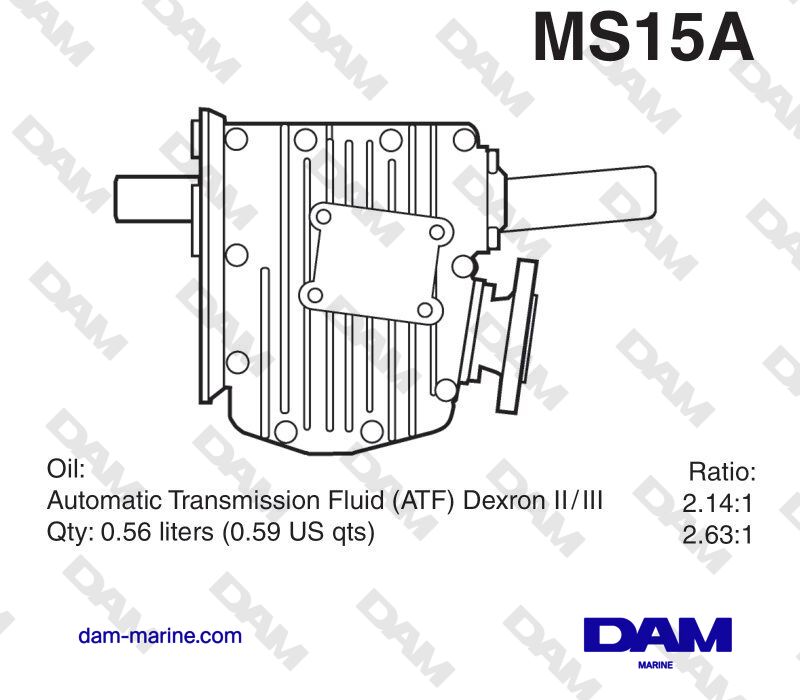

MS15A

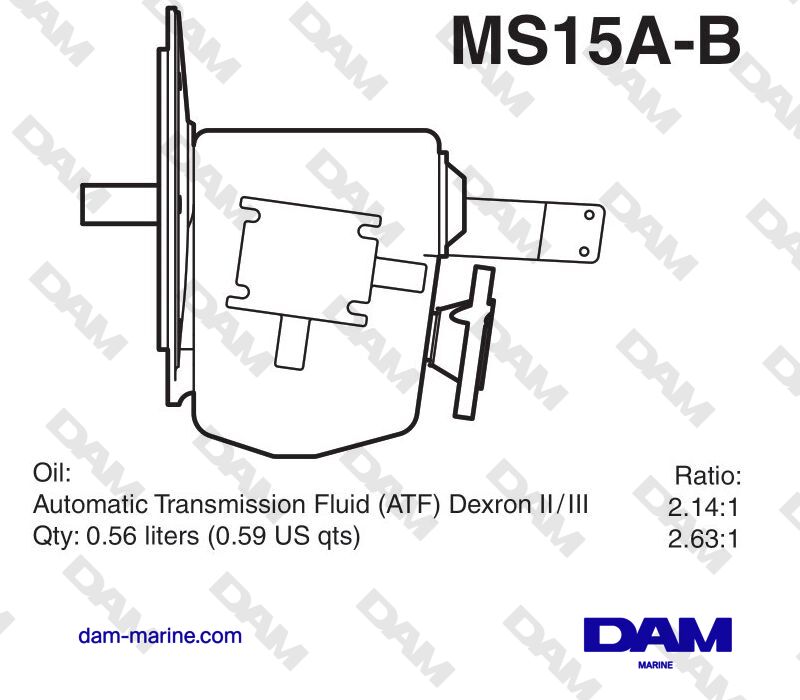

MS15A-B

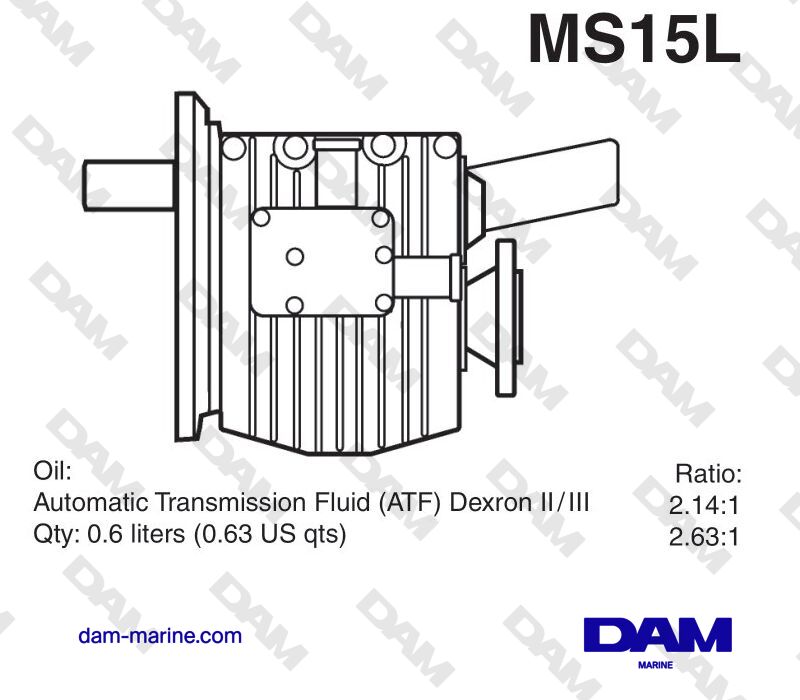

MS15L

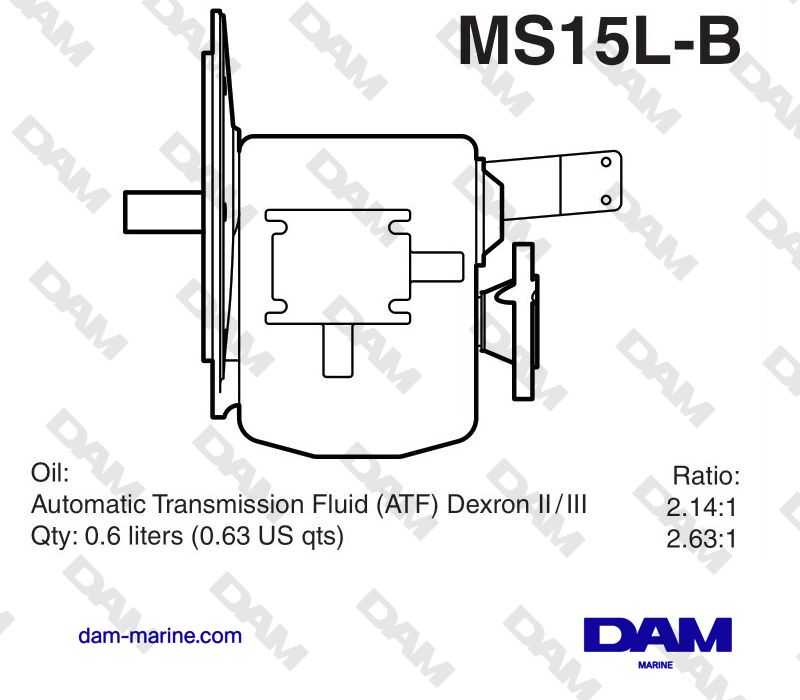

MS15L-B

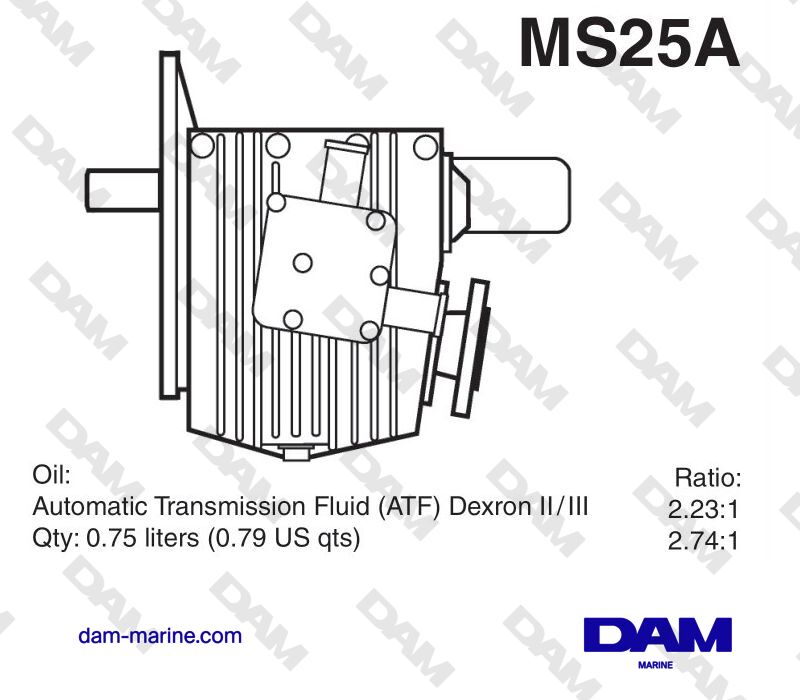

MS25A

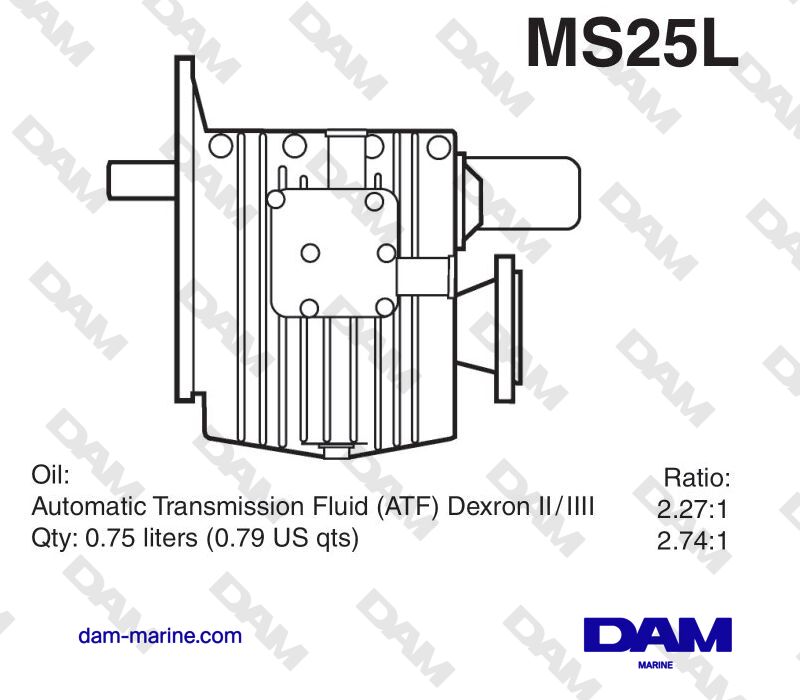

MS25L

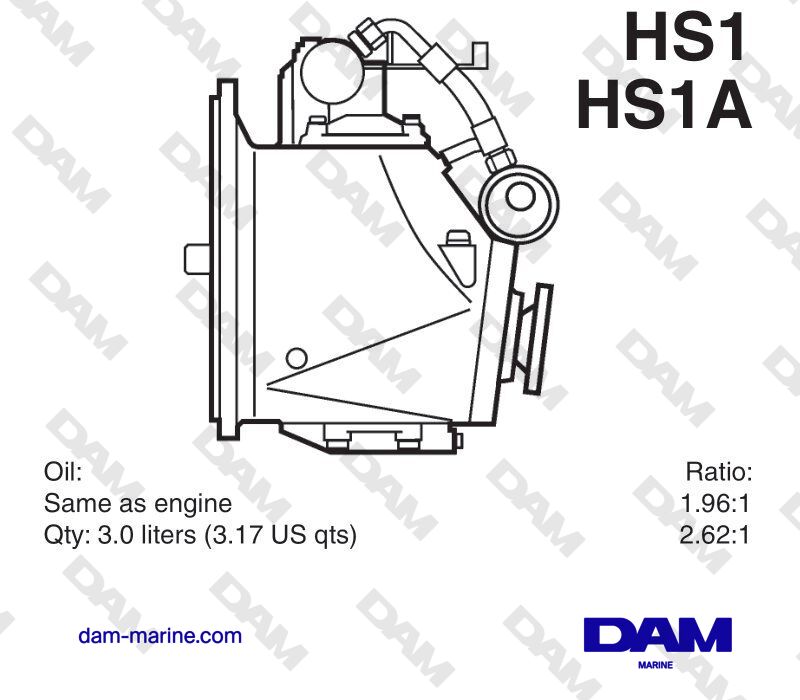

HS1 / HS1A

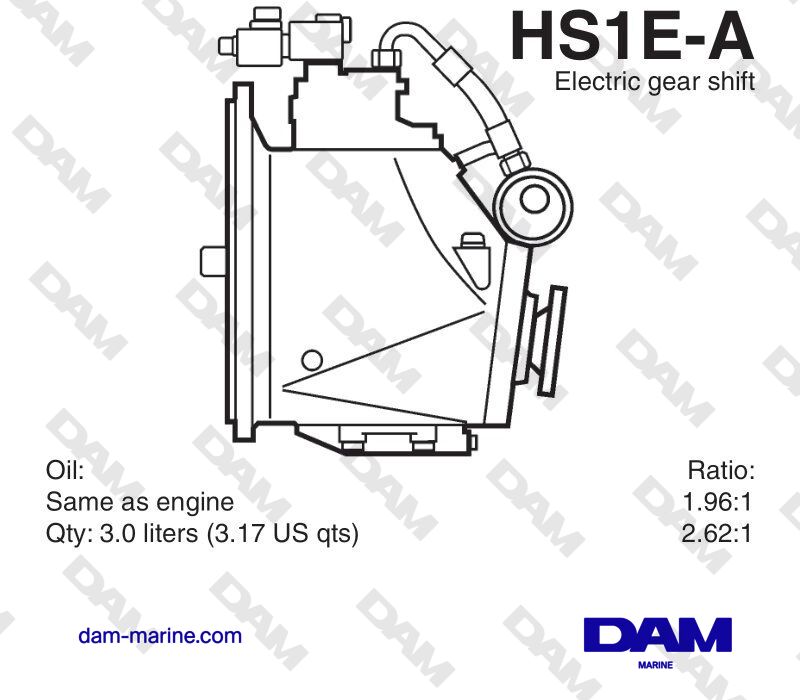

HS1E-A

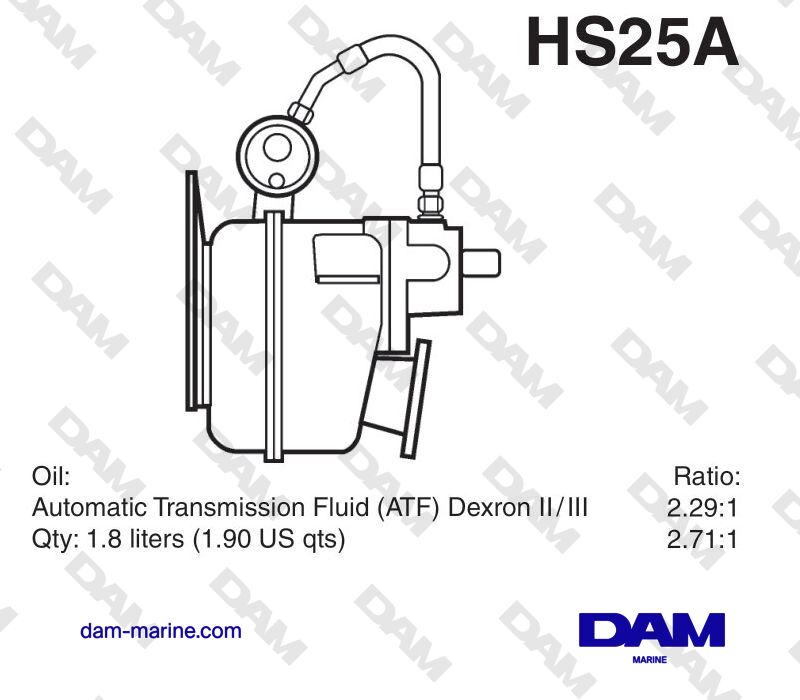

HS25A

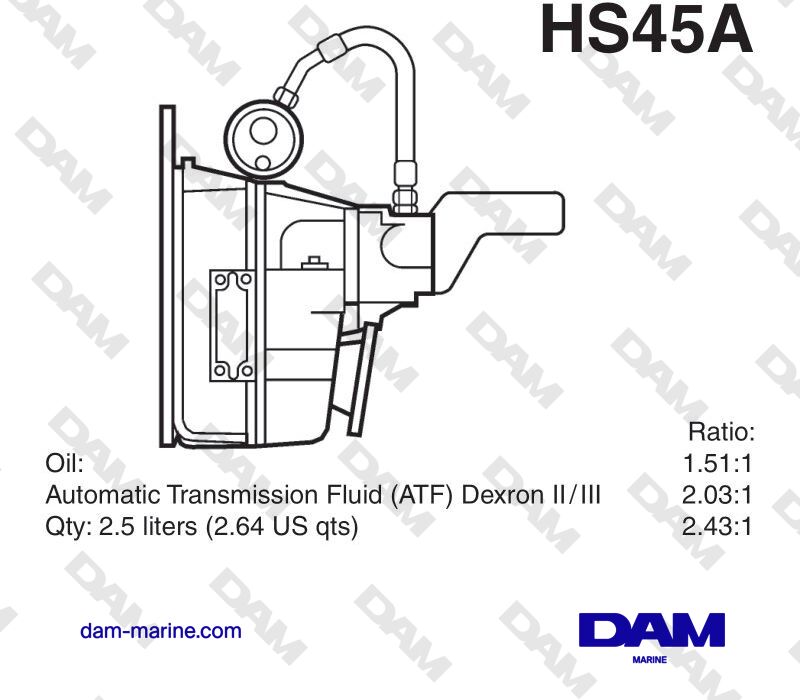

HS45A

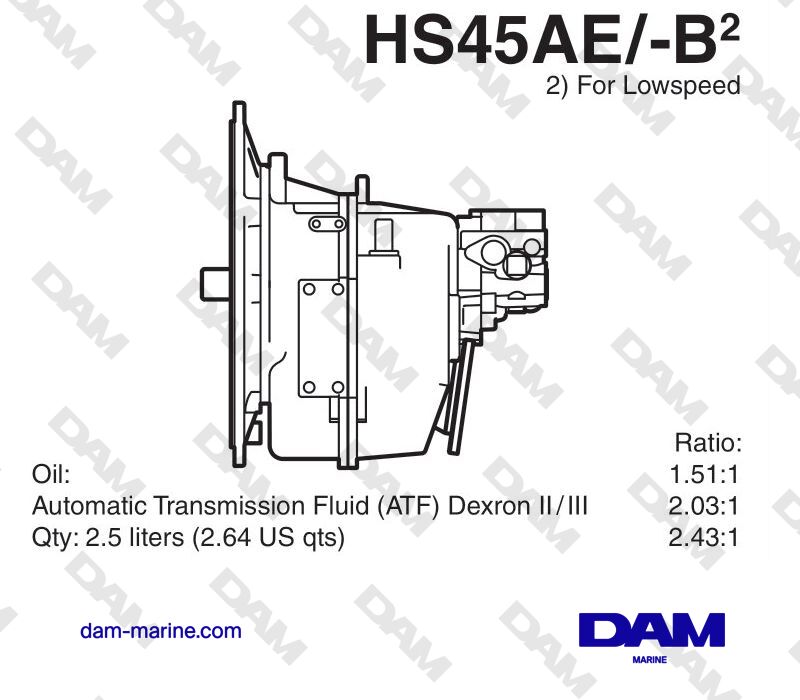

HS45AE/-B

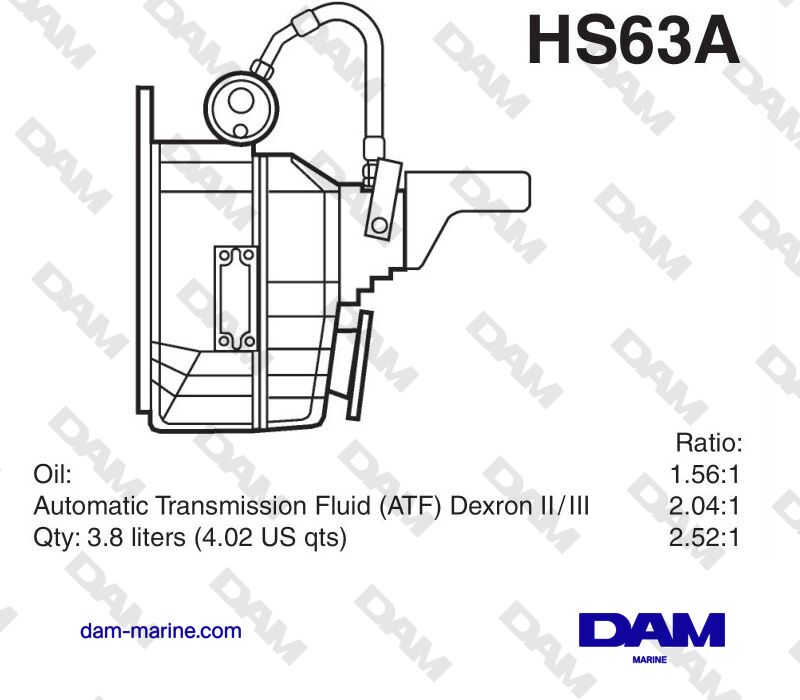

HS63A

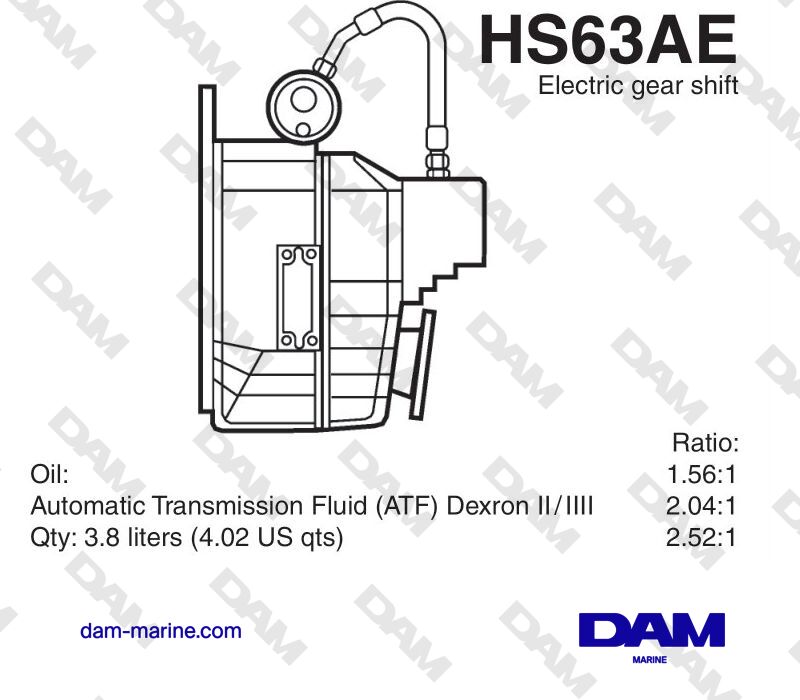

HS63AE

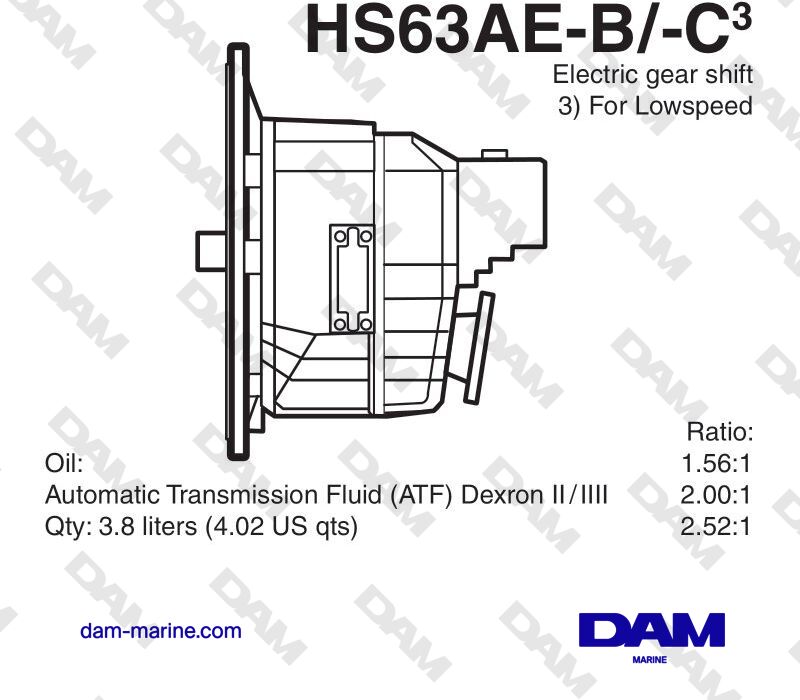

HS63AE -B -C

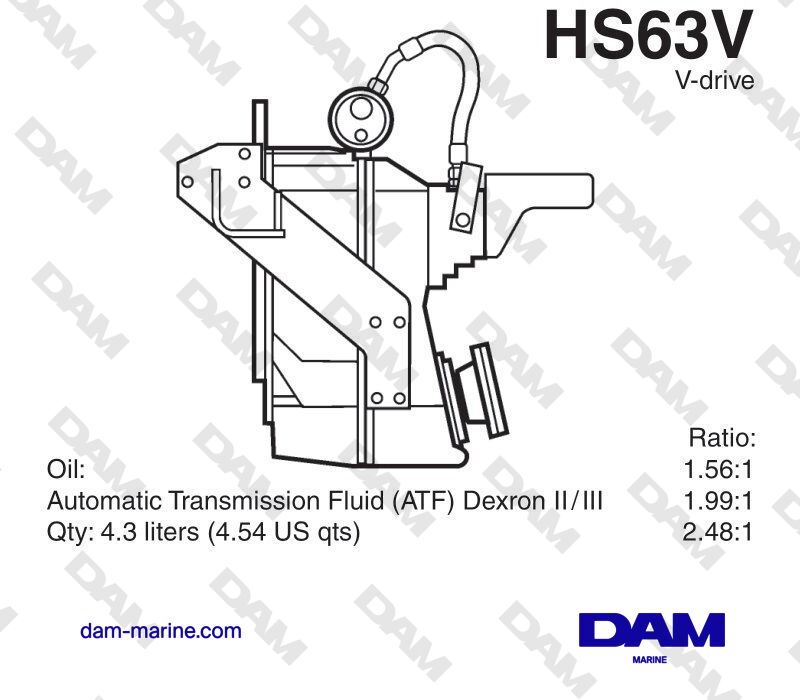

HS63V (V-Drive)

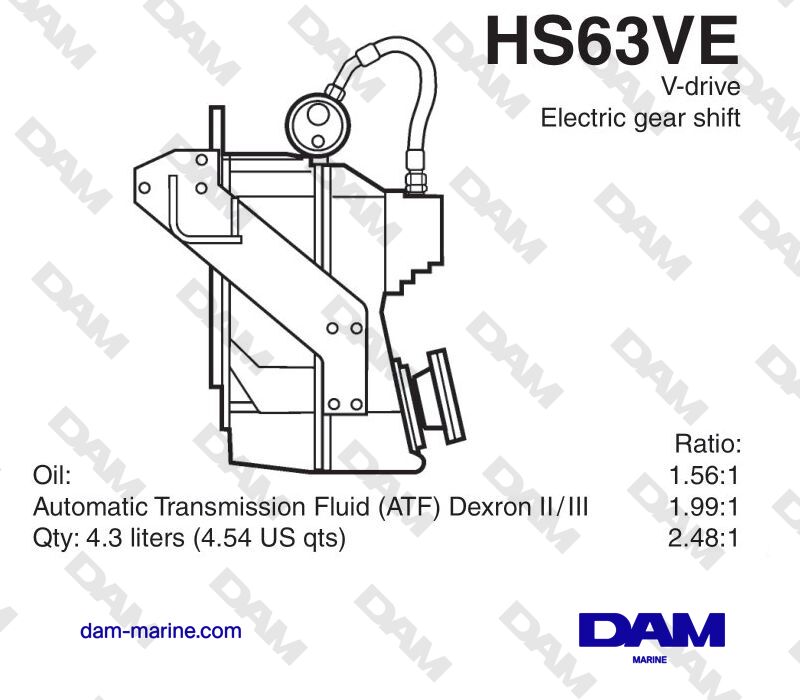

HS63VE

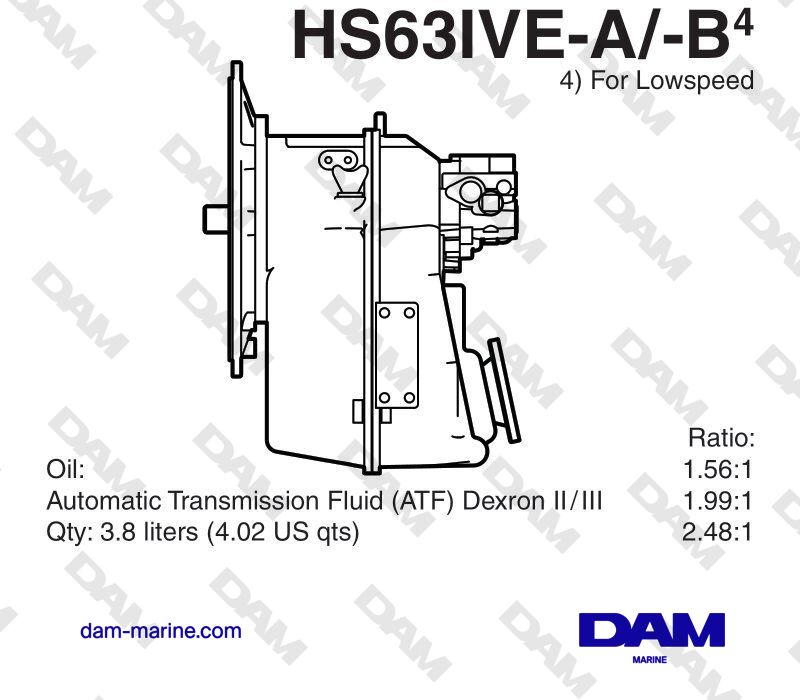

HS63IVE-A / -B

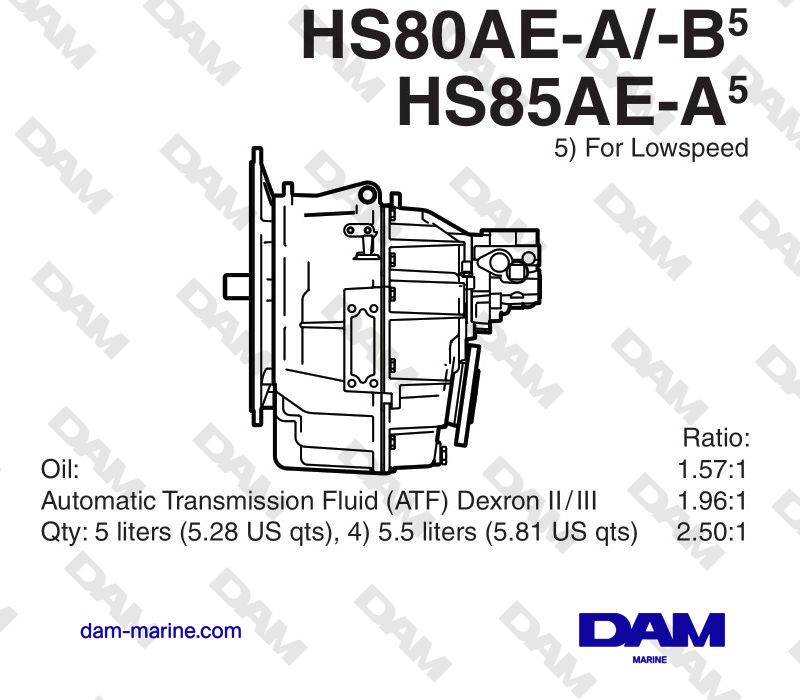

HS80AE - A / - B

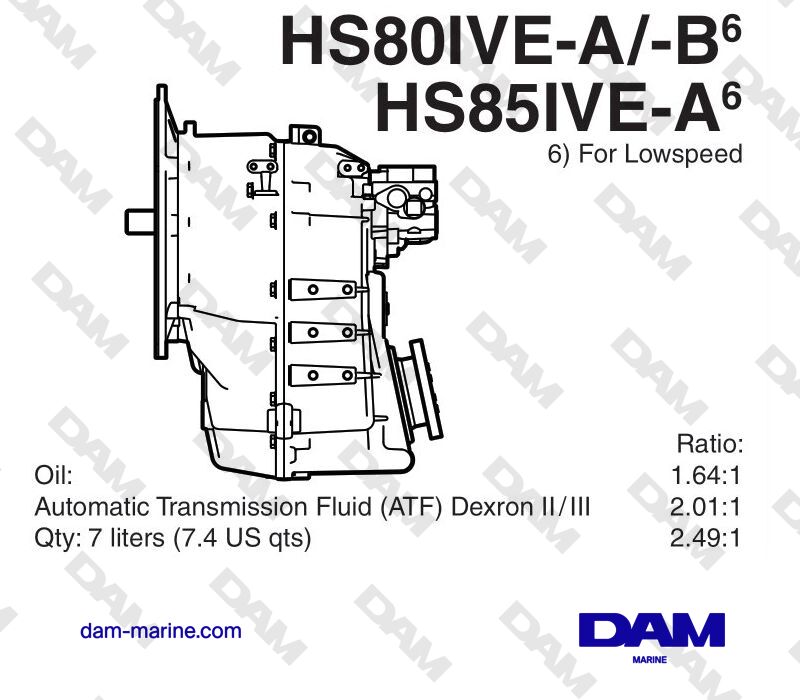

HS80IVE-A/-B

| Moteur | Huile 15W40 (L) | Liquide (L) | Commentaire |

|---|---|---|---|

| 1GM10 | 2 | NA | |

| 2YM15 | 2 | 4 | |

| 3YM20 | 3 | 5 | |

| 3YM30AE | 3 | 5 | |

| 3JH5 | 5 | 5 | |

| 3JH40 | 5 | 5 | |

| 4JH45/57 | 5 | 7 | |

| 4JH80/110 | 7 | 8 | |

| 4LHA | 13 | 20 | Coolant 16L |

| 4LV | 10 | 10 | Coolant 11L |

| 6LPA | 10 | 20 | Coolant 16L |

| 6LY2 | 20 | 25 | |

| 6LY3 | 20 | 30 | |

| 6LY400/440 | 20 | 25 | Coolant 22L |

| 8LV | 10 | 20 |

| Liter | Huile 5W40 (L) | Liquide (L) | Commentaire |

|---|---|---|---|

| 4BY3 | 7 | 13 | Oil 8L, Coolant 11L |

| 6BY3 | 10 | 15 | Oil 11L, Coolant 14L |

| Inverseur Type | Huile (L) | Liquide (L) | Commentaire |

|---|---|---|---|

| SD25 (1GM10) | 10W30 3 | 3 | Changer en cas de 1GM10C |

| SD25 | SAE30 3 | 3 | |

| SD60-4; SD60-5 | 15W40 3 | 3 | |

| KM2P-1 | SAE30 1 | 1 | |

| KM35A(2) | SAE30 1 | 1 | |

| KM35P | SAE30 1 | 1 | |

| KM4A2 | SAE30 2 | 2 | 3L |

| KMH4A | SAE30 2 | 2 | |

| KMH41A | SAE30 2 | 2 | |

| KMH50A-3 | SAE30 3 | 3 | 2L |

| KMH51A | SAE30 3 | 3 | |

| KMH50V - 52V | SAE30 6 | 6 | 5.4L |

| KMH60A | SAE30 3 | 3 | |

| KMH61A | SAE30 3 | 3 | |

| KMH61V | SAE30 8 | 8 | |

| KMH70A | SAE30 8 | 8 | |

| ZF15MIV | ATF 1 | 1 | |

| ZF25 - ZF25A | ATF 2 | 2 | |

| ZF30M | ATF 1 | 1 | 1.1L |

| ZF45 - ZF45A | ATF 3 | 3 | |

| ZF63 - ZF63A | ATF 4 | 4 | |

| ZF63IV | ATF 4 | 4 | |

| ZF220 | SAE30 5 | 5 | |

| ZF280 | SAE30 5 | 5 | |

| ZT370 | HPG | 3 | Inverseur |

| ZT370 | ATF-1L | 2 | Système hydraulique (EPS, TRIM) |

| Parts | References |

|---|---|

| Maintenance kit | SKMARINE001 |

| Oil filter | 119305-35170 |

| Fuel filter gasket | 24341-000440 |

| Diesel filter | SN21587 |

| Air filter | 128170-12540 |

| Turbine | 128176-42071 |

| Water pump cover gasket | 128170-42090 |

| Water pump plate | 128170-42080 |

| Motor anode | 27210-200200 |

| Yanmar anode gasket | 123210-09310 |

| Thermostat | 105582-49200 |

| Thermostat cover gasket | 104211-49160 |

| Alternator belt | 128170-77350E |

| Parts | References |

|---|---|

| Maintenance kit | SKMARINE001 |

| Oil filter | 119305-35170 |

| Fuel filter gasket | 24341-000440 |

| Diesel filter | SN21587 |

| Air filter | 128170-12540 |

| Turbine | 128176-42080 |

| Water pump cover gasket | 128170-42090 |

| Water pump plate | 128170-42080 |

| Motor anode | 27210-200200 |

| Yanmar anode gasket | 123210-09310 |

| Thermostat | 105582-49200 |

| Thermostat cover gasket | 104211-49160 |

| Alternator belt | 128170-77350E |

| Parts | References |

|---|---|

| Oil filter | 104271-35130 |

| Diesel filter | 104300-55790 |

| O-ring for diesel filter | 24311-000320 |

| Turbine | 19210-ZW9-A32 |

| Cooling turbine | 104211-42071 |

| Pump cover gasket | 104211-42090 |

| Water pump cover | 104211-42080 |

| Zinc anodes | 104211-41300 |

| Anode gasket | 123210-09310 |

| Thermostat | 105582-49200 |

| Thermostat gasket | 104211-49160 |

| Alternator belt | 104211-42780E |

| Water pump belt | 104214-42780E |

| Rocker cover gasket | 104200-11310 |

| Cylinder head gasket | 104264-01331 |

| Parts | References |

|---|---|

| Oil filter | 104271-35130 |

| Diesel filter | 104300-55790 |

| O-ring for diesel filter | 24311-000320 |

| Cooling turbine | 104211-42071 |

| Pump cover gasket | 104211-42090 |

| Water pump cover | 104211-42080 |

| Zinc anodes | 104211-41300 |

| Anode gasket | 123210-09310 |

| Thermostat | 105582-49200 |

| Thermostat gasket | 104211-49160 |

| Alternator belt | 104211-42780E |

| Water pump belt | 104214-42780E |

| Rocker cover gasket | 104200-11310 |

| Cylinder head gasket | 104264-01331 |

Show More >>

Understanding the Engine Control Module (ECM)

The Engine Control Module (ECM), also known as the Engine Control Unit (ECU), is an essential component of modern vehicles. Find out how it works and why it's important.

Functions of the ECM

- Engine management: Monitors and controls functions such as fuel injection and ignition timing.

- Sensor data processing: Receives information to optimise performance and reduce emissions.

- Diagnostics: Performs self-diagnostics to detect faults and store error codes.

- Fuel efficiency: Adjusts parameters to improve fuel economy.

- Performance optimisation: Makes real-time adjustments to improve power and responsiveness.

Components interfacing with the ECM

The ECM interacts with various components:

- Sensors: Provide data on critical parameters such as engine temperature.

- Actuators: Devices such as fuel injectors, controlled by the ECM.

- Communication networks: Connect the ECM to other vehicle control modules.

Importance of the ECM

- Emissions control: Enables compliance with environmental standards.

- Performance reliability: Ensures optimum engine operation.

- User experience: Improves acceleration, fuel economy and driveability.

Common problems

The following problems can affect the ECM:

- Faulty sensors: lead to reduced performance or increased emissions.

- Software bugs: require updates to correct problems.

- Electrical problems: disrupt communication between the ECM and other components.

Conclusion

The ECM plays an essential role in modern vehicles by balancing performance, efficiency and emissions control. Remember to carry out regular diagnostics to detect and resolve problems.

| Embases Volvo | Quantité | Indice | Voir les huiles |

|---|---|---|---|

| AQ100 | 2.5L | 75W90 | Voir les huiles > |

| AQ200 | 2L | 75W90 | Voir les huiles > |

| AQ250/270 | 2.2L | 75W90 | Voir les huiles > |

| 280/290/SP-A | 2.6L | 75W90 | Voir les huiles > |

| 280DP/290DP/DP-D/DP-E | 2.7L | 75W90 | Voir les huiles > |

| DPG | 3.1L | 75W90 | Voir les huiles > |

| SX | 2.1L | 75W90 | Voir les huiles > |

| DP-S/DP-SM | 2.4L | 75W90 | Voir les huiles > |

| 100S | 2.5L | 75W90 | Voir les huiles > |

| 110S | 1.8L | 75W90 | Voir les huiles > |

| 120S | 2.6L | 75W90 | Voir les huiles > |

| 150S | 3L | 15W90 | Voir les huiles > |

| MS25 | 2.0L | 75W90 | Voir les huiles > |

| DPH | 5.2L | 75W90 | Voir les huiles > |

| DPR | 4.2L | 75W90 | Voir les huiles > |

| HS1 | 3L | 75W90 | Voir les huiles > |

| Embases Mercruiser | Quantité | Indice | Voir les huiles |

|---|---|---|---|

| Alpha One G2 | 1.16L | SAE90 | Voir les huiles > |

| Alpha One G2 + Bocale | 1.9L | SAE90 | Voir les huiles > |

| Bravo I | 1.9L | SAE90 | Voir les huiles > |

| Bravo I + Bocale | 2.6L | SAE90 | Voir les huiles > |

| Bravo II | 2.4L | SAE90 | Voir les huiles > |

| Bravo II + Bocale | 3.1L | SAE90 | Voir les huiles > |

| Bravo III | 1.9L | SAE90 | Voir les huiles > |

| Bravo III + Bocale | 2.8L | SAE90 | Voir les huiles > |

| Embases Yanmar | Quantité | Indice | Voir les huiles |

|---|---|---|---|

| KM4A1-5 | 1.3L | SAE30=MOTEUR | Voir les huiles > |

| KM4A | 1.3L | SAE30=MOTEUR | Voir les huiles > |

| KM2P | 0.3L | SAE20/30 | Voir les huiles > |

| SD25 | 2.2L | 10W30 | Voir les huiles > |

| KM35P | 0.5L | SAE20/30=MOTEUR | Voir les huiles > |

| KM35A | 0.65L | SAE20/30 | Voir les huiles > |

| SD60 | 2.8L | SAE20/30 | Voir les huiles > |

| KM4A1-5 | 2.3L | SAE20/30 | Voir les huiles > |

| ZF30M | 1.1L | ATF | Voir les huiles > |

| KM4A2-4 | 2L | SAE20/30 | Voir les huiles > |

| KMH4A | 2L | SAE20/30 | Voir les huiles > |

| ZF25A | 1.8L | ATF | Voir les huiles > |

| SD20/30/40/50 | 2.2L | MERC HP | Voir les huiles > |

| Yanmar reverser | Quantity | Index | See oils |

|---|---|---|---|

| HSW 630A1 | 4,5L | ATF | See oils > |

| KMH4A | 2L | ATF | See oils > |

| KMH6A | 4L | ATF | See oils > |

| KMH6A1 | 4L | ATF | See oils > |

| SD31 | 2,2L | MERC HP | See oils > |

| SD40-T | 2,2L | MERC HP | See oils > |

| KBW10E | 0,7L | ATF | See oils > |

| KBW20 | 1,2L | ATF | See oils > |

| KBW20-1 | 1,2L | ATF | See oils > |

| KBW21 | 1,2L | ATF | See oils > |

| KM3A | 0,45L | ENGINE | Same oil as the engine |

| KM3P | 0,35L | ENGINE | Same oil as engine |

| KM3P4 | 0,35L | ENGINE | Same oil as engine |

| KM3V | 0,8L | SAE30=ENGINE | See oils > |

| KM5A | 2.1L | SAE30 | See oils > |

Show More >>

Réglage - Moteur à l'arrêt

1. Après que le moteur ait atteint la température de fonctionnement normale, retirez les couvercles de soupapes et installez des arrêtoirs de culbuteur pour empêcher l'huile de gicler sur tout le moteur.

2. Avec le moteur au ralenti, desserrez les écrous des bras de culbuteur (un à la fois) jusqu'à ce que le bras de culbuteur commence à cliqueter.

3. Serrez l'écrou du bras du culbuteur jusqu'à ce que le cliquetis cesse.

4. Serrez l'écrou d'un quart de tour supplémentaire et faites une pause de 10 secondes jusqu'à ce que le moteur tourne en douceur. Répétez jusqu'à ce que l'écrou ait été serré de trois quarts de tour à partir de la position de jeu nul.

IMPORTANT : Ce réglage de précharge de trois quarts de tour doit être effectué lentement pour permettre au poussoir de s'ajuster lui-même, évitant ainsi la possibilité d'interférence entre la tête de la soupape et le sommet du piston, ce qui pourrait entraîner des dommages internes et/ou tordre des tiges de poussoir.

5. Faites tourner le moteur d'un tour complet jusqu'à ce que la marque de l'indicateur "PMH (Point Mort Haut)" et la marque de l’amortisseur de torsion soient à nouveau alignées. C'est la position d'allumage n°6. Avec le moteur dans cette position, voir la Figure 8-122 pour des informations sur les soupapes qui peuvent être réglées.

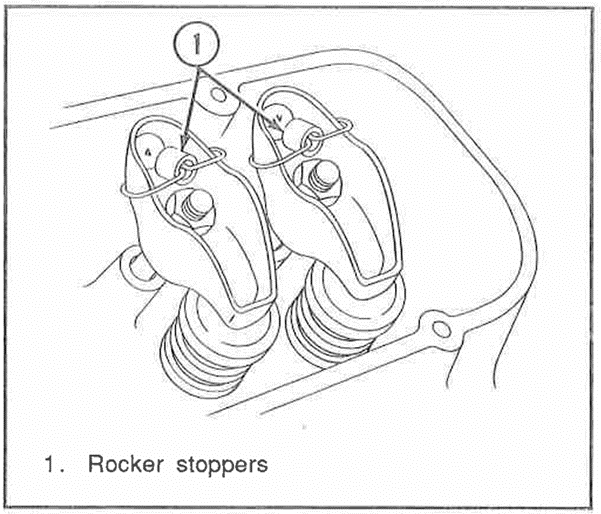

1. After the engine has reached normal operating temperature, remove the valve covers and fit the rocker arm stops to prevent oil splashing everywhere.

2. With the engine idling, loosen the rocker arm nuts (one at a time) until the rocker arm starts to rattle.

Fig. 8-123 Installed rocker arm stops

3. Turn the rocker arm nut until the clicking stops. This is the backlash-free position.

4. Turn the nut a further quarter turn and pause for 10 seconds until the engine runs smoothly. Repeat until the nut has been turned a further 3/4 turn from the backlash-free position.

5. Repeat steps 2, 3 and 4 to adjust the remaining valves.

6. Remove the rocker arm stops after all the valves have been adjusted.

7. After adjusting the valves, complete the following operations:

a. Install a new gasket and fit the covers. Tighten to the specified torque.

b. Start the engine and check for leaks.

c. Adjust the carburettor idle speed and mixture.